Flex PCB Adhesives and Bonding Guide

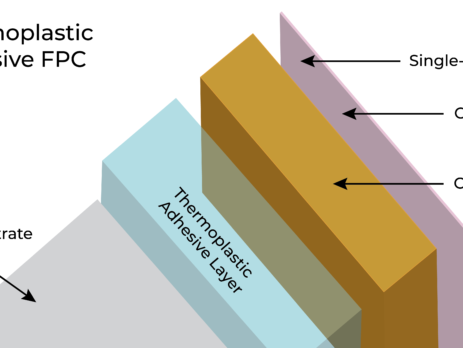

Thermoplastic vs thermoset adhesives, adhesiveless constructions, and the process factors that drive delamination riskIn flex circuits, reliability is not determined by copper and substrate alone. A large share of real-world failures trace back to the bond line. Bond systems influence peel strength, bend durability, thermal survivability through...