Overmolding Services

Advanced Protection for Electronic Assemblies

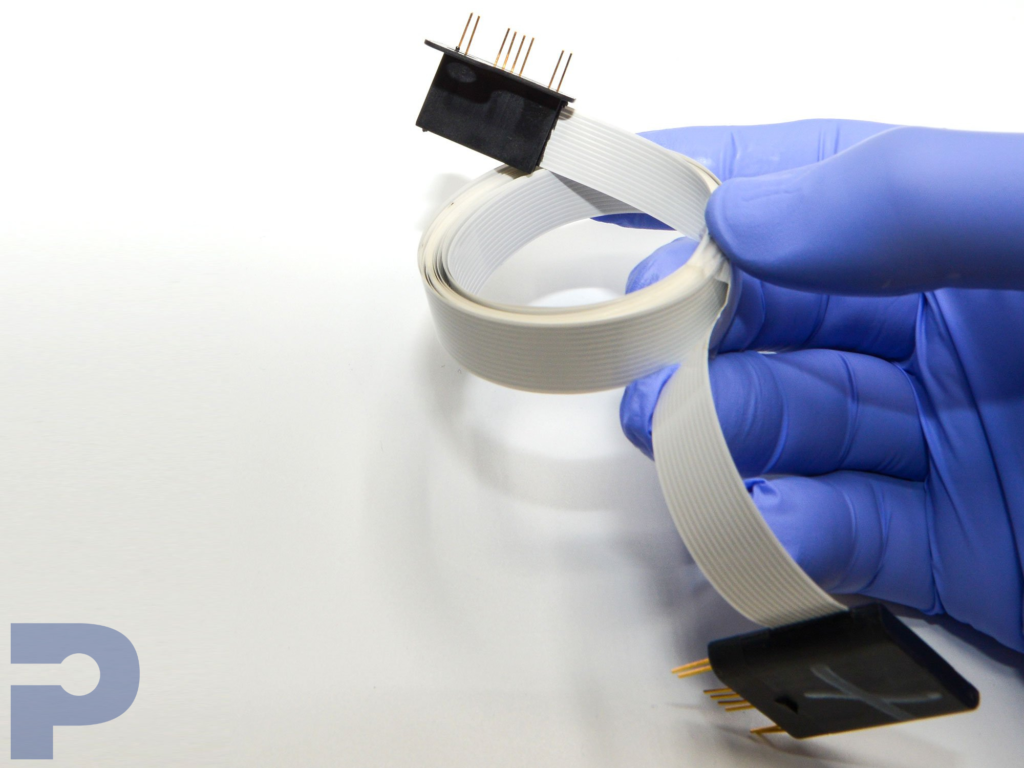

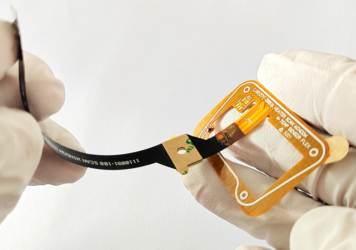

PICA Manufacturing Solutions provides advanced overmolding services to enhance the durability, protection, and functionality of electronic assemblies. Using durable thermoplastic or elastomeric materials, our overmolding process encapsulates PCBs, connectors, and wire harnesses—creating a sealed, ruggedized layer that protects against moisture, vibration, strain, and environmental exposure.

By integrating overmolded electronics into your design, you can reduce the need for secondary enclosures, streamline product assembly, and improve long-term reliability in demanding applications. From functional prototypes to high-volume runs, PICA delivers custom solutions built for the mechanical and environmental challenges of modern electronic systems.

Why Choose PICA for Overmolding?

Custom Solutions – Tailored overmolding for flex circuits, connectors, cables, and user interfaces.

Material Expertise – Thermoplastics and elastomers selected for durability, ergonomics, and compliance.

Precision Tooling – High-quality molds engineered to support complex geometries and repeatability.

Scalable Production – From prototype validation to high-volume manufacturing runs.

Integration Ready – Overmolding designed to align seamlessly with PCB and electronic assemblies.

Overmolding Capabilities (Highlights)

Thermoplastic and elastomeric overmolding

Direct overmolding onto PCBs, flex circuits, and wire harnesses

Multi-material and complex geometry support

Strain relief for cable assemblies

Ergonomic and functional enhancements for user interfaces

Benefits of Overmolding

Enhanced Protection

Encapsulation shields electronics from moisture, vibration, mechanical stress, and environmental exposure.

Improved Reliability

By sealing sensitive areas, overmolding increases durability and reduces failure rates in harsh applications.

Design Flexibility

Supports complex geometries, ergonomic enhancements, and multi-material designs tailored to user needs.

Reduced Assembly Costs

Eliminates secondary housings or enclosures, simplifying builds and lowering overall system costs.

Better User Experience

Overmolding improves ergonomics, grip, and product aesthetics, enhancing functionality and usability.

Markets & Applications

Medical Devices

Sealed, biocompatible assemblies for portable monitors, sensors, and patient-safe interfaces.

Automotive & Transportation

Durable overmolded harnesses, connectors, and modules resistant to vibration and environmental stress.

Industrial Equipment

Ruggedized electronics for robotics, automation, and heavy-duty environments.

Consumer Electronics

Custom grips, enclosures, and strain-relieved cables that improve usability and durability.

Defense & Aerospace

Encapsulated assemblies that withstand extreme conditions and ensure mission-critical reliability.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

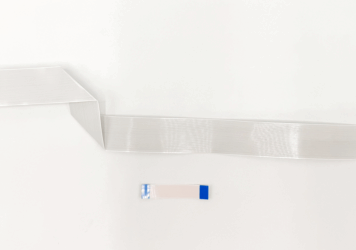

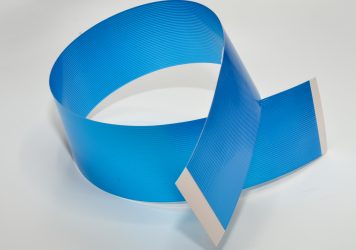

Flat Flexible Cables (FFC): A Cost-Effective and Scalable Interconnect Solution

For engineers balancing performance, flexibility, and cost, Flat Flexible Cables (FFC) remain one of the most efficient...

Conductive Inks and Their Role in Flexible and Printed Electronics

Conductive Inks and Their Role in Flexible and Printed ElectronicsAs electronics continue to evolve beyond rigid, boxy enclosures, the materials...

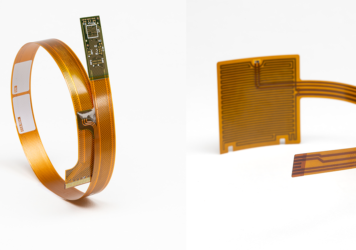

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

Understanding Flexible Printed Circuit (FPC) Cost Drivers

Flexible Printed Circuits (FPCs) are essential components in modern electronics, enabling lightweight, compact, and high-performance designs. However, they come...

Common Mistakes Made by PCB Designers When Designing Flexible Circuits (FPCs)

Flexible Printed Circuits (FPCs) are widely used due to their lightweight, flexible, and compact nature, making them ideal for...

The Overmolding Solution

The Customer: A manufacturer in the motorcycle industry sought to enhance the design of their motorcycle steering wheels. They required...

Shielding Solutions to Protect Your FFC Cables

Ever increasing signal speeds and high noise environments make EMI/RFI shielding an essential requirement for FFC’s (Flat Flexible...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.