Hybrid PCB Assemblies: Combining Technologies for Smarter Designs

Custom Hybrid PCB Assemblies Engineered for Performance

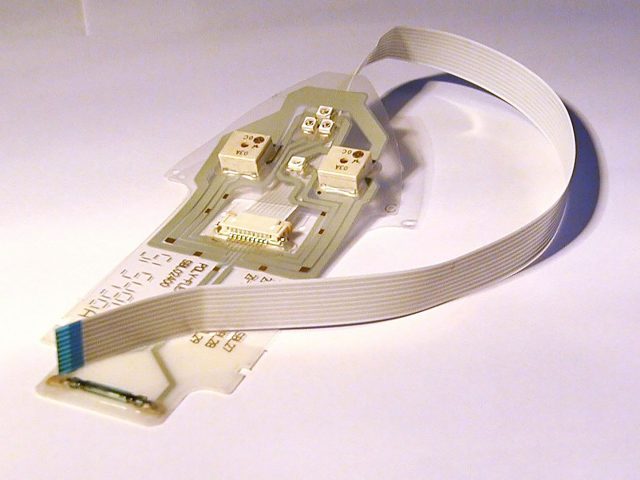

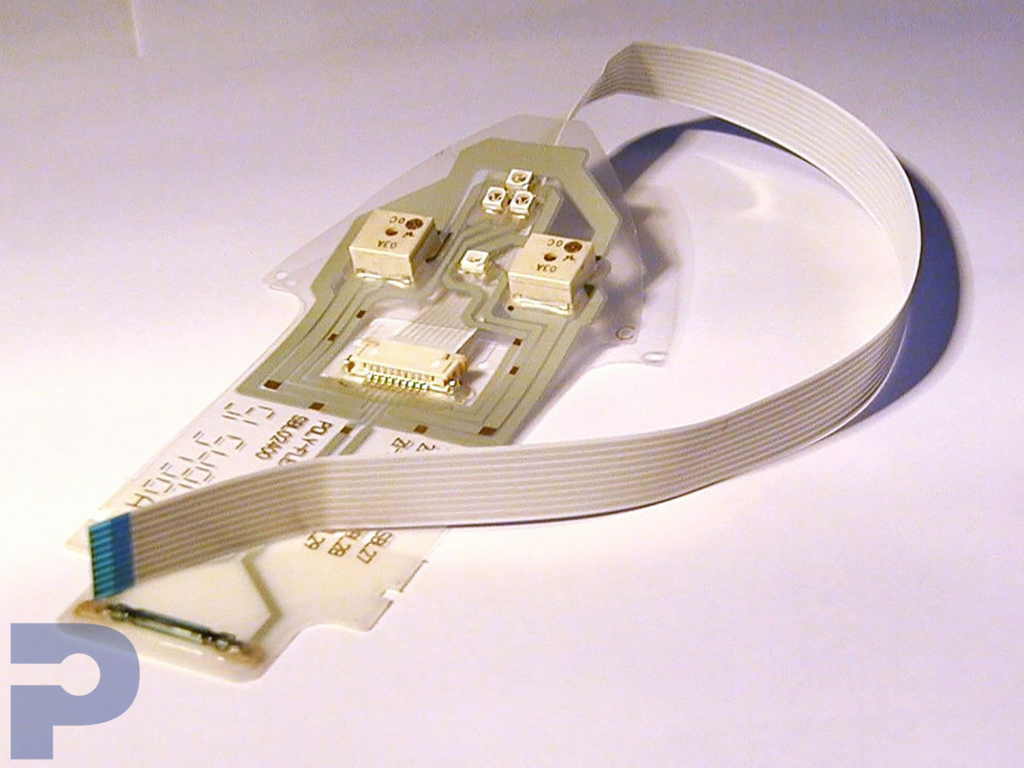

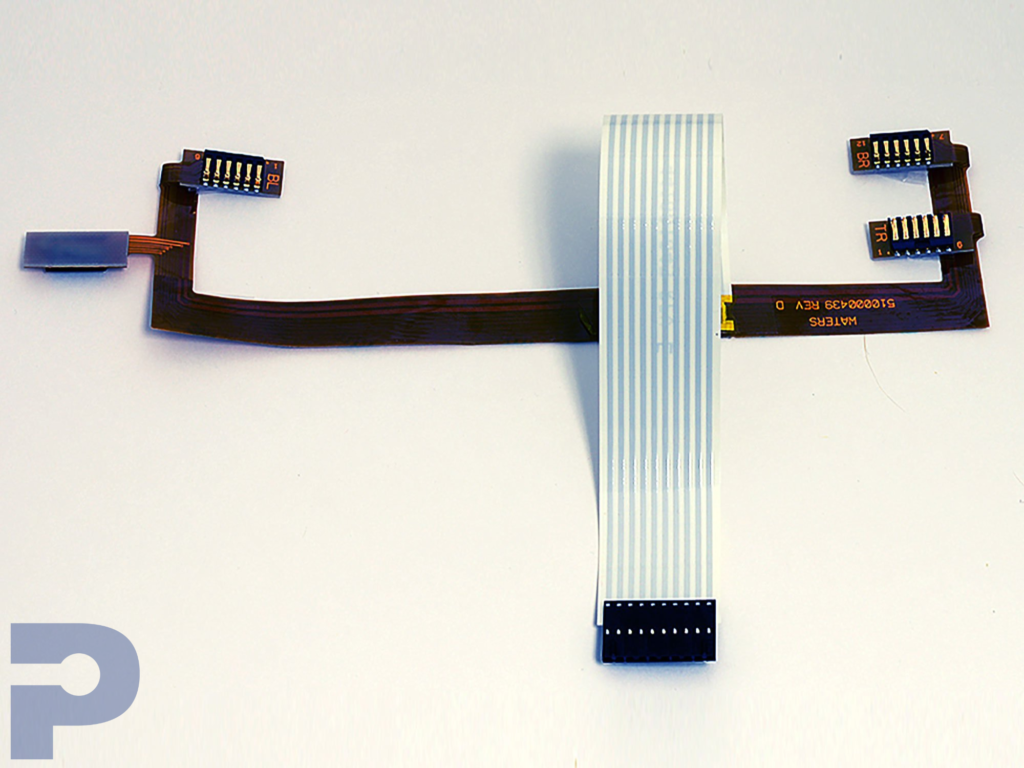

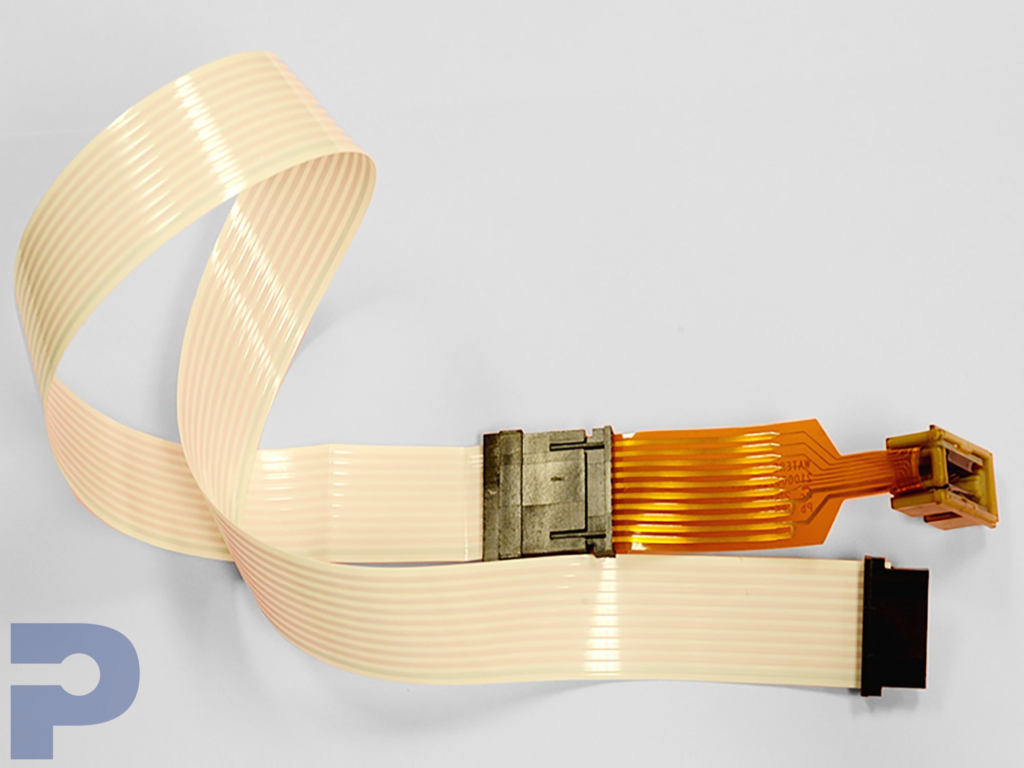

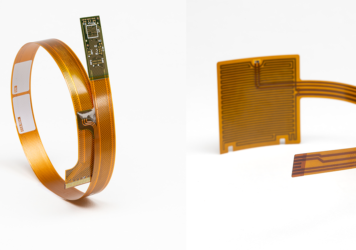

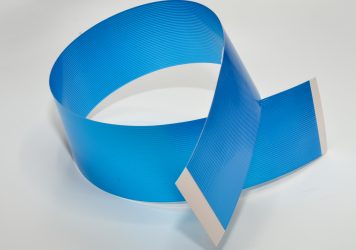

PICA Manufacturing Solutions specializes in Hybrid PCB Assemblies that combine multiple interconnect technologies — rigid, flex, flat flexible cables (FFC), wire harnesses, and metal core PCBs — into a single, highly integrated solution. This approach enables compact, efficient, and reliable electronic systems that meet the toughest design and performance requirements.

Whether you need rigid-flex integrated with wire harnesses, FFC embedded into flexible circuits, or multi-layer metal core designs, PICA delivers assemblies that simplify layouts, reduce connectors, and improve system-level performance.

Why Choose Hybrid PCB Assemblies?

Optimized Space – Combine multiple technologies into one assembly to minimize connectors and save space in compact enclosures.

Enhanced Reliability – Fewer interconnect points reduce failure risks, improving durability in high-stress environments.

Better Electrical Performance – Integrated designs improve signal integrity and support high-speed applications.

Design Flexibility – Take advantage of both rigid strength and flexible routing in one solution.

Cost Efficiency – Reduced parts and simplified assembly lower overall system costs.

Hybrid PCB Capabilities – Highlights

PICA combines advanced materials, precision processes, and multi-technology expertise to deliver hybrid solutions such as:

Rigid-flex + wire harness integration

Embedded FFC within flex circuits

Metal core + FR-4 hybrid stack-ups for thermal performance

Controlled impedance and high-speed signal routing

Adhesiveless polyimide, RA copper, and EMI shielding options

Seamless PCBA integration with custom assembly services

Benefits of Hybrid PCB Assemblies

Space Efficiency

Combining rigid, flex, FFC, and harnesses into one assembly saves valuable space in compact or irregular enclosures.

Improved Reliability

Fewer connectors and interconnects reduce potential failure points, ensuring stronger long-term performance.

Electrical Performance

Integrated designs minimize impedance mismatches and improve signal integrity across high-speed applications.

Design Flexibility

Hybrid assemblies merge rigid stability with flexible routing, enabling creative layouts and complex 3D designs.

Cost Savings

Consolidating parts and reducing assembly steps lowers overall production costs and simplifies the supply chain.

Markets We Serve with Hybrid PCB Assemblies

Medical Devices

Ideal for implants, diagnostic systems, and surgical tools requiring biocompatibility, reliability, and miniaturization.

Consumer Electronics

Enable compact, lightweight devices like smartphones, wearables, and tablets with hybrid designs that reduce bulk and improve durability.

Automotive

Support advanced driver systems, sensors, and lighting with hybrids that withstand vibration, temperature shifts, and harsh conditions.

Industrial

Hybrid assemblies strengthen robotics, automation, and control systems by combining rugged durability with space-efficient designs.

Defense & Security

Withstand extreme environments in satellites, avionics, and military systems where lightweight, reliable performance is mission critical.

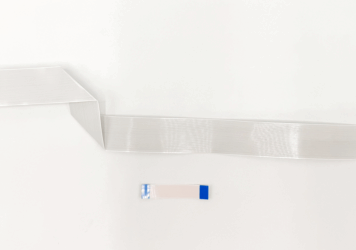

Flat Flexible Cables (FFC): A Cost-Effective and Scalable Interconnect Solution

For engineers balancing performance, flexibility, and cost, Flat Flexible Cables (FFC) remain one of the most efficient...

Conductive Inks and Their Role in Flexible and Printed Electronics

Conductive Inks and Their Role in Flexible and Printed ElectronicsAs electronics continue to evolve beyond rigid, boxy enclosures, the materials...

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

Adhesiveless Technologies for Flexible Circuits: Unlocking Next-Generation Performance

In the world of flexible electronics, the shift from traditional flexible copper-clad laminates (FCCLs) to adhesiveless materials represents a significant...

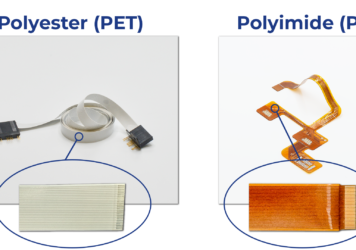

Flexible Printed Circuit (FPC) Dielectric Materials: Choosing the Best for Your Application

At PICA Manufacturing Solutions (PMS), we specialize in creating Flexible Printed Circuits (FPCs) that enable innovative designs by conforming...

6-Layer ELIC Rigid Flex Printed Circuit Board / Rigid Flex PCB

A 6-Layer ELIC (Every Layer Inter-connect) Rigid Flex Printed Circuit Board / Rigid Flex PCB is an advanced and...

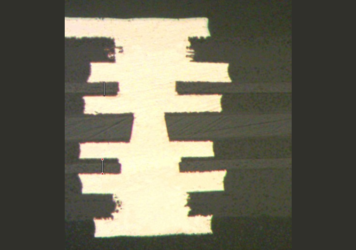

Shielding Solutions to Protect Your FFC Cables

Ever increasing signal speeds and high noise environments make EMI/RFI shielding an essential requirement for FFC’s (Flat Flexible...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.