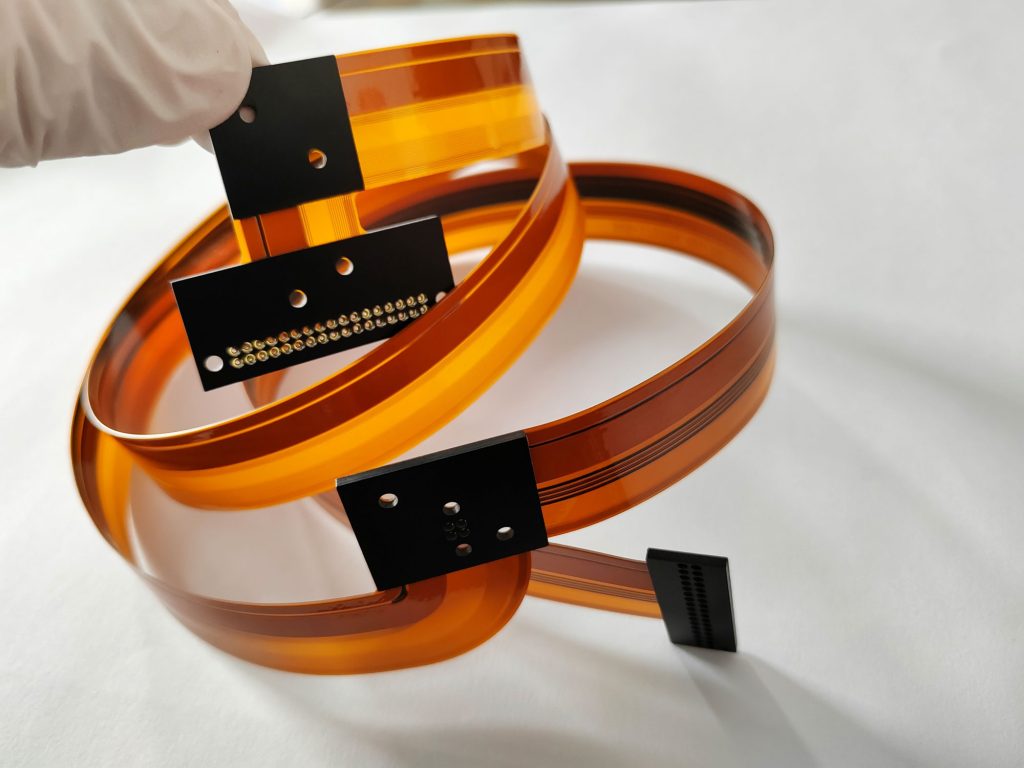

Extra-Long Flex Printed Circuits (FPC) for High-Reach Applications

Flexible Printed Circuits Engineered for Length, Precision & High-Performance

When your design demands a flex circuit that spans meters in length instead of inches, standard FPC suppliers won’t cut it. PICA specializes in extra-long flexible printed circuits — up to 3,000 mm (118 in) — with top tier dimensional accuracy, flatness, minimal shrinkage and tailored process methods (panel-based or roll-to-roll).

Why Choose Extra-Long Flex Printed Circuits?

- Exceptional Length Capability – Supports spans up to 3,000 mm (118 in) for genomics, automation, medical imaging, security scanning and more.

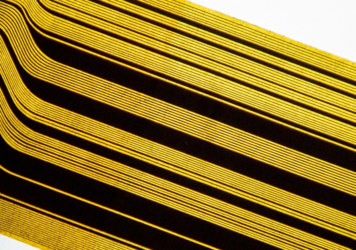

- Dimensional Precision & Flatness – Tight tolerances on thickness (min 0.13 mm, tolerance ±0.03 mm), alignment (±0.1 mm) and profile (±1 mm to ±5 mm depending on length).

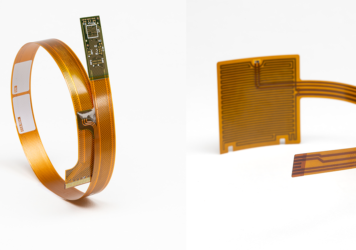

- Manufacturing Flexibility – Both panel-based and roll-to-roll (RTR) processing paths allow optimization for multi-layer precision or high-volume run lengths.

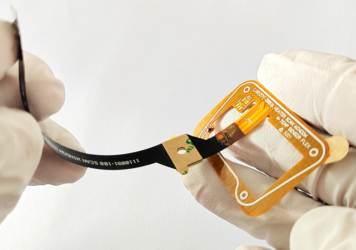

- Support for Demanding Use Cases – Ideal for applications where the flex circuit spans long distances, integrates with moving parts, or eliminates multiple connectors/harnesses.

- Engineering-Driven DFM & Manufacturability – Early collaboration to manage stiffeners (SUS), finger-designs, backing, tolerance build-up and shrinkage issues for extra-long formats.

Extra-Long Flex Printed Circuits Capabilities – Highlights

- Lengths up to 3,000 mm (118 inches).

- Standard widths of 250 mm and 500 mm, thickness down to 0.13 mm (± 0.03 mm).

- Alignment tolerance of ±0.1 mm, profile tolerance between ±1 mm to ±5 mm depending on length.

- Two primary manufacturing methods:

• Panel-Based Processing — precision multi-layer, tighter tolerances.

• Roll-to-Roll (RTR) Processing — high-volume single- or double-layer flexible circuits. - Design guidance for extra-long builds: use of SUS stiffeners for dimensional stability; stiffener edges placed ≥ 0.5 mm from critical features; finger-designs with solid or no copper-backing; tapered / recessed plug-and-pull fingers by 0.2 mm.

- Ideal for medical, automation, security surveillance, wearables and industrial systems requiring long interconnect spans and high-flex reliability.

Global Design & Manufacturing Support

PICA partners with your engineers early to define stack-ups, tolerances, stiffeners and shrink-control strategies for extra-long flex circuits. We guide process selection (panel or roll-to-roll), support prototyping through volume builds, and ensure manufacturable, stable results across extreme lengths.

Benefits of Extra-Long Flex Printed Circuits

Extendable Reach

Long-span flex circuits eliminate multiple connectors and harnesses by providing a continuous circuit from point A to B — reducing assembly complexity and failure points.

Precision Across Length

Tight control of thickness, alignment and profile means a board that remains flat, reliable and dimensionally sound even at extreme lengths.

Volume-Optimised Manufacturing

With both panel and RTR methods, you can select the most cost-effective, high-throughput approach for your length, layer and volume requirements.

Reliability in Challenging Use Cases

Whether in medical imaging gantries, onboard security scanners, long-reach robotics or wearable/industrial systems, certified extra-long flex circuits stand up to real-world stresses.

Design Freedom & Product Simplification

Long flex circuits free you from mini-harnessing, allow creative form factors, reduce interconnect transitions and simplify your bill-of-materials (BOM).

Markets We Serve with Extra-Long Flex Printed Circuits

Industrial Automation & Robotics

Deploying long-reach sensors, scanning arms, conveyor systems and robotic modules benefits from extra-long, single-piece flex circuits instead of complex wire bundles.

Medical Imaging & Diagnostics

Ultrasound probes, imaging tables, long-span patient monitors, diagnostics equipment — require precise, long flex paths with tight flatness and minimal shrinkage.

Security, Surveillance & Scanning Systems

X-ray tunnels, body scanners, baggage inspection, surveillance systems employ flex circuits that span the entire device, in ultra-long formats with high reliability.

Wearables, Transportation & Mobile Systems

Flexible assemblies in vehicles, e-mobility, large-format displays or foldable platforms that need extended flex lengths and efficient interconnects.

Consumer/Display & Large-Format Electronics

Displays, foldables, large span interconnects (e.g., rollable displays, extended sensor arrays) require flex circuits built for length, flatness and precision.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

Understanding Flexible Printed Circuit (FPC) Cost Drivers

Flexible Printed Circuits (FPCs) are essential components in modern electronics, enabling lightweight, compact, and high-performance designs. However, they come...

Common Mistakes Made by PCB Designers When Designing Flexible Circuits (FPCs)

Flexible Printed Circuits (FPCs) are widely used due to their lightweight, flexible, and compact nature, making them ideal for...

Ultra-Thin Flexible Circuits: Overcoming Challenges in Dielectric Substrate

In Part 1, we explored the challenges of manufacturing ultra-thin flexible circuits with a focus on the conductive layers, highlighting...

Building Ultra-Thin Flexible Circuits: Part 1 – Conductor

One of our key customers approached PICA with the challenge of manufacturing ultra-thin flexible circuits. A critical component of this...

Adhesiveless Technologies for Flexible Circuits: Unlocking Next-Generation Performance

In the world of flexible electronics, the shift from traditional flexible copper-clad laminates (FCCLs) to adhesiveless materials represents a significant...

Compliance: Ensuring Safety and Performance in Flexible Printed Circuit Manufacturing

When developing and manufacturing flexible printed circuits (FPCs), adhering to industry standards ensures reliability, safety, and performance. Two pivotal standards...