Fineline & HDI Printed Circuits

Ultra-Fine-Pitch, High-Density Circuits for Compact, High-Performance Electronics

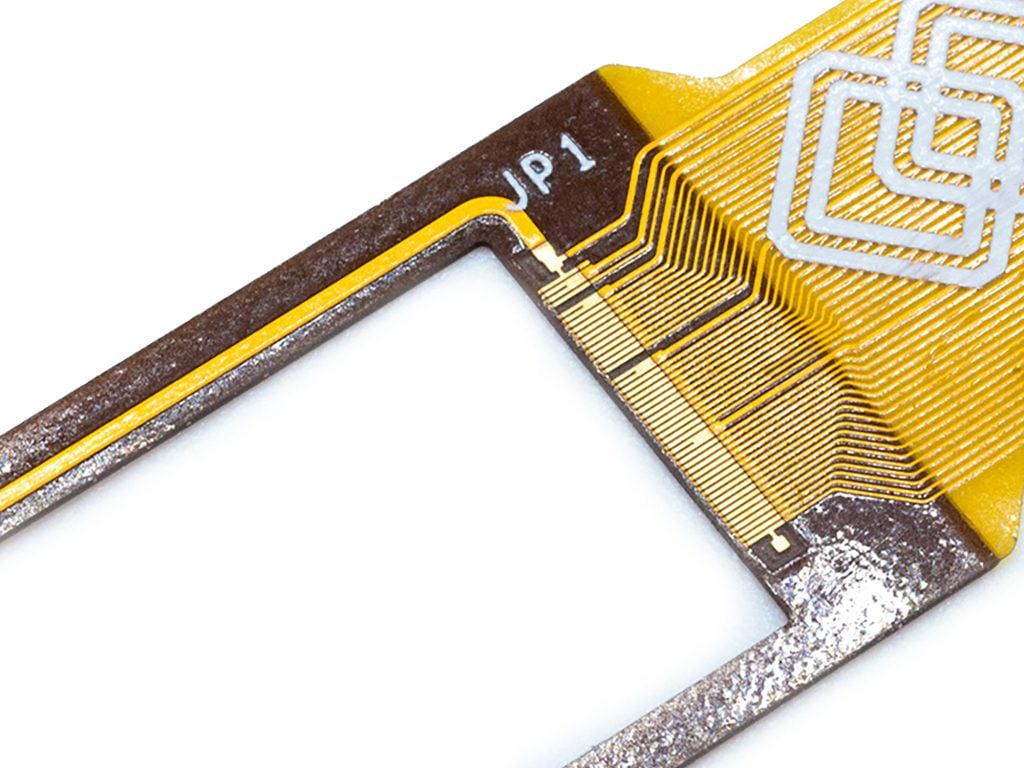

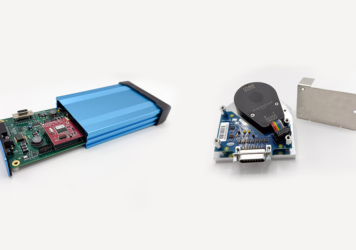

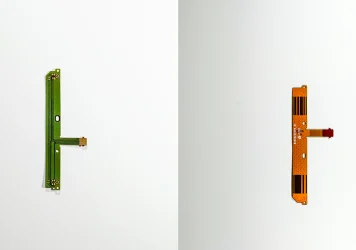

Fineline and HDI (High Density Interconnect) printed circuit boards are engineered to support miniaturization, high-speed signals, and dense component integration. PICA’s advanced PCB and flex manufacturing enables fine-line trace widths, laser micro-vias, ultra-thin dielectrics, and multi-build-up stack-ups that meet the demands of today’s wearable, RF, medical, automotive and high-frequency systems.

Why Choose Fineline / HDI Printed Circuits?

• Superior Component Density – Enables packing more I/O and functionality in a smaller footprint.

• Ultra-Fine Trace Capability – Achieve line/space down to 25–50 µm, using subtractive or mSAP/mSAP-like processing.

• Micro-Via & Via-In-Pad Support – Laser-drilled micro-vias, stacked or staggered, allow escape routing from dense BGAs and high-pin-count packages.

• High-Speed & RF-Ready Performance – Controlled impedance, ultra-thin dielectrics (as low as 12–25 µm) and low-loss materials support high-frequency and mixed-signal designs.

• Manufacturability & Reliability – Early DFM engagement, strict etching control, and 100% AOI ensure high yields in fine-line builds.

• Flex-HDI & Dynamic-Flex Options – Combine flexible arms + HDI cores or even dynamic-flex fine-line sections for moving applications.

Fineline PCB Capabilities – Highlights

• Laser Direct Imaging (LDI) for line/space ≈1 mil (≈25 µm) in rigid, flex, and rigid-flex builds.

• Ultra-Thin Copper options including rolled-annealed (RA) and thin electrolytic foils for improved fine-line routing and bend reliability.

• Multi-build-up HDI stack-ups such as 1+N+1, 2+N+2, and flex HDI buildup structures.

• Blind, buried, stacked and staggered micro-vias ≤ 0.15 mm with copper fill and via-in-pad options.

• Modified Semi-Additive Process (mSAP / mSAP-like) for <50 µm fine-line routing and controlled sidewall geometry.

• Thin dielectric materials (down to ~12–25 µm) for impedance targets, RF performance, and compact trace separation.

• Integrated rigid-flex HDI, dynamic flex + fine-line hybrid designs, and thin-core options for harsh environments.

• Inspection & Quality Assurance: AOI, X-Ray, flying probe, impedance verification, and micro-section analysis.

• Engineering Support: early layout review, stack-up optimization, micro-via strategy, reliability modeling, and material selection.

For technical information on PICA’s Fineline Flex PCB capabilities, click the button below.

Global Design & Manufacturing Support

With engineering teams in the U.S. and manufacturing in Malaysia, PICA supports prototypes through scaled production. We collaborate early to optimize stack-ups, choose low-loss materials, refine micro-via strategy, tune line/space limitations, and control impedance from Day 1. This prevents cost overruns, improves yield, and accelerates time-to-market for high-density builds.

Benefits of Fineline / HDI Circuits

High-Density Designs

Fineline/HDI builds enable greater routing density and component placement in smaller form factors—ideal for compact RF, sensor, and high-speed modules.

Enhanced Signal Integrity

Ultra-thin dielectrics, tight trace spacing, and precise etching improve impedance accuracy, reduce skew, and maintain low-loss transmission paths.

Miniaturization-Ready

Sub-50 µm traces and stacked micro-vias enable smaller boards, more features, and lighter assemblies without sacrificing reliability.

Manufacturing Efficiency

Controlled etching, LDI, copper fill via-in-pad, and automated inspection deliver high first-pass yield and minimized scrap—reducing total cost.

Dual-Flexibility

HDI isn’t limited to rigid boards. PICA supports rigid-flex HDI and dynamic-flex fine-line builds, enabling motion + density in one circuit.

Markets We Serve with Fineline / HDI Circuits

Mobile & Wearable Devices

Foldables, compact wearables and IoT modules rely on ultra-dense PCB real-estate and precision interconnects—ideal for HDI and flex HDI.

Medical Devices

Miniaturized sensors, implantables, and micro-assemblies demand ultra-fine routing, controlled impedance, and high-reliability micro-vias.

Automotive & Transportation

ADAS modules, radar systems and harsh-environment controls benefit from fine-line HDI that withstands vibration and thermal stress.

Telecommunications & 5G Infrastructure

RF modules, mmWave antenna arrays, and interposers require ultra-thin dielectrics, fine-line routing and stable impedance control.

Industrial & Defense Electronics

Rugged systems in UAVs, aerospace, and high-density sensor modules rely on fine-line durability, reliability, and extreme miniaturization.

The blogs featured below expand on this page’s content, offering detailed insights into specific design, manufacturing, and application topics that provide added relevance and deeper context for engineers and decision-makers.

Flex PCB Substrate Deep Dives Beyond Polyimide

PET vs PEN, LCP, PTFE/fluoropolymers, and specialty films like PEI/PEEK: when each wins, where each struggles, and what it means...

Highlights from MD&M WEST 2026

MD&M West 2026 in Anaheim brought together medtech, automation, design/manufacturing, plastics, and packaging, so the biggest trend wasn’t one...

Tariffs in the United States: History, Reality, and How PICA Helps You Navigate Them

Tariffs have played a role in the U.S. economy since the nation’s founding. In the early days of the republic,...

CES 2026 Highlights: The Breakthrough Technologies Powered by Advanced Flex & PCB Design

Las Vegas, January 2026 — CES 2026 once again confirmed that the pace of innovation in consumer tech, mobility,...

What Is Box Build Assembly? Process, Benefits & How to Choose a Manufacturer

Box build assembly—sometimes called systems integration—involves assembling a complete electronic product by combining a finished PCBA with...

Designing PCBs for Medical Devices: Key Considerations & Compliance Tips

PCB design for medical electronics demands more than just electrical functionality. Devices must meet...

What to Look for in a Manufacturing Company in Malaysia

When evaluating a manufacturing company in Malaysia, most teams are focused on a few essentials: capability fit, reliable quality systems,...

LPI Solder Mask vs. Polyimide Coverlay: Choosing the Right Protection for Flexible Circuits

Protecting the copper circuitry on a flexible printed circuit (FPC) is essential to ensuring long-term reliability and...