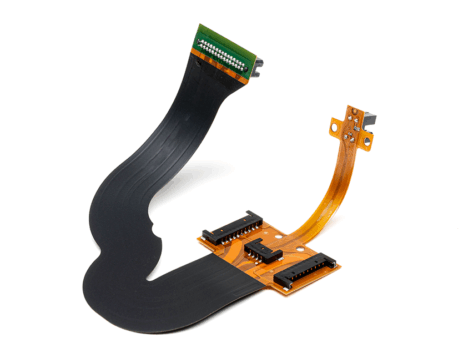

Auxiliary Materials in Flex PCB Builds

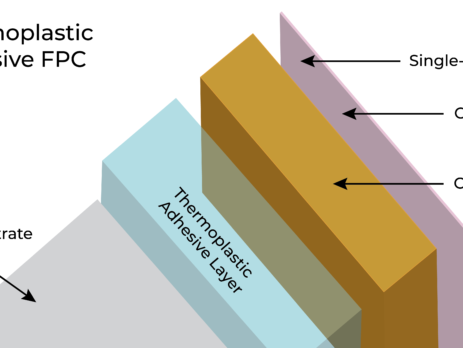

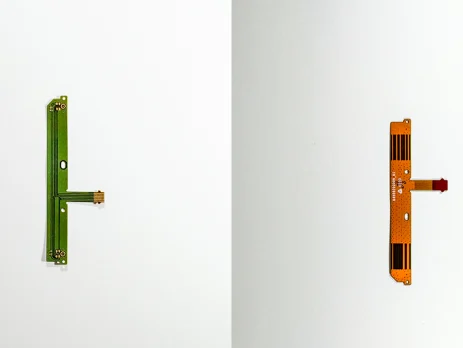

Stiffener, EMI Shielding, Release liners, spacers, marking inks, thermally conductive adhesive films, and PSA selection guidance.When engineers talk about flex PCB materials, the focus is usually on the core stack-up: substrate film, copper, adhesives, and coverlay. But many reliability and assembly issues are driven...