Rigid Flex Circuit Boards / Rigid Flex PCB

Custom Rigid-Flex Circuit Boards Engineered for Reliability

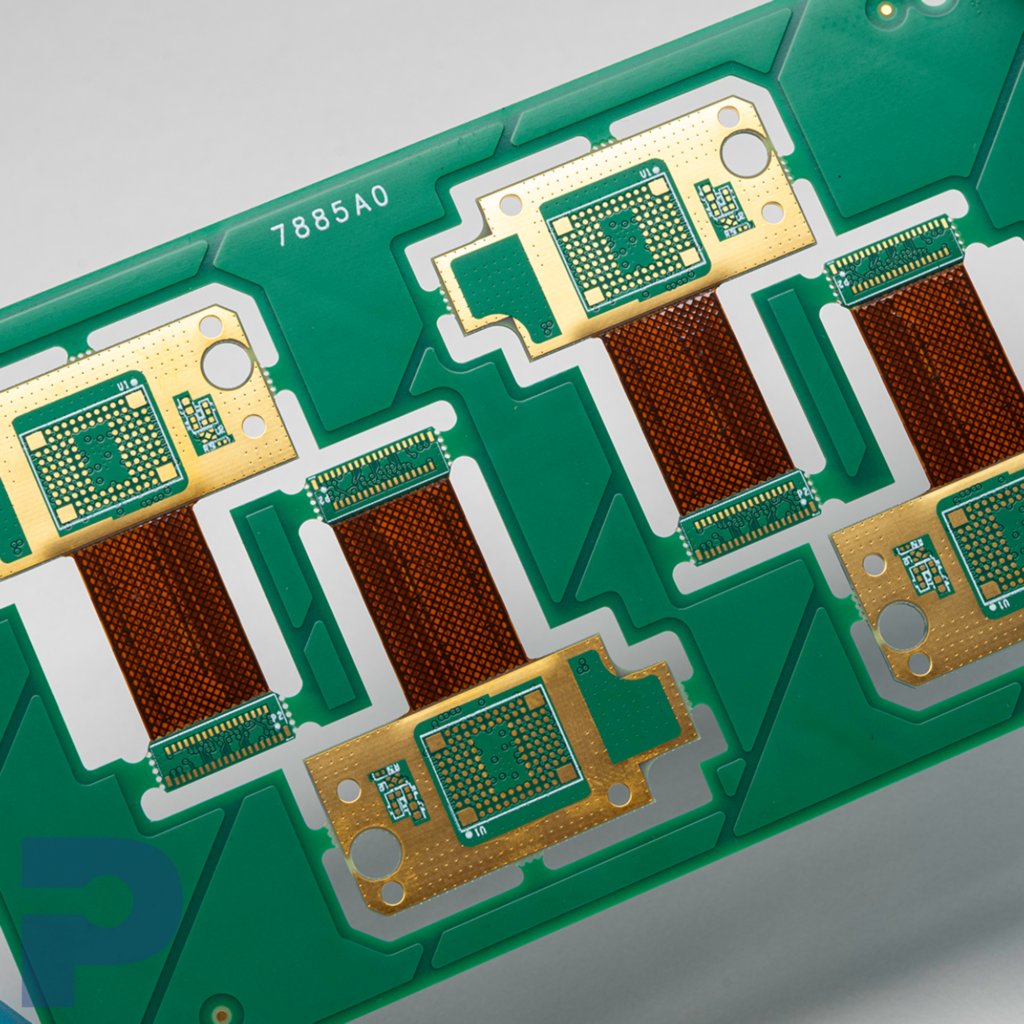

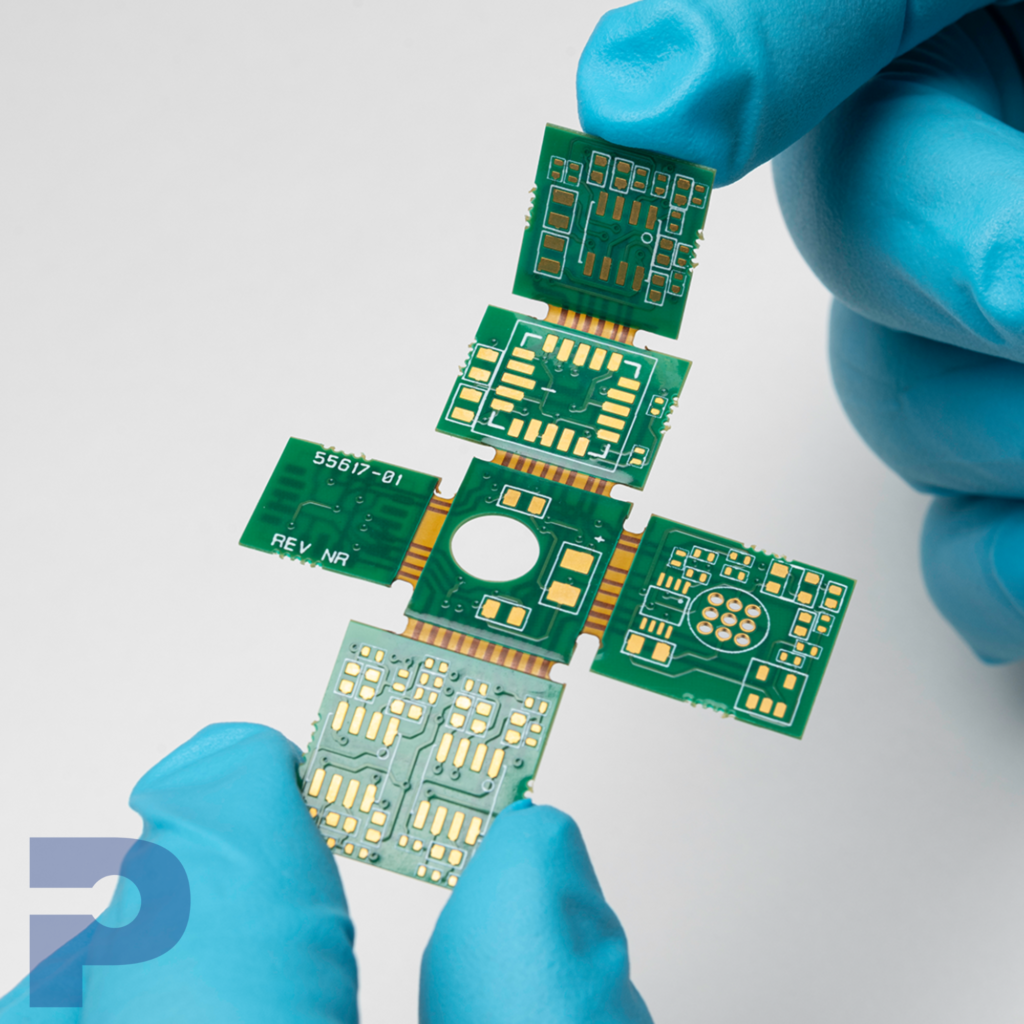

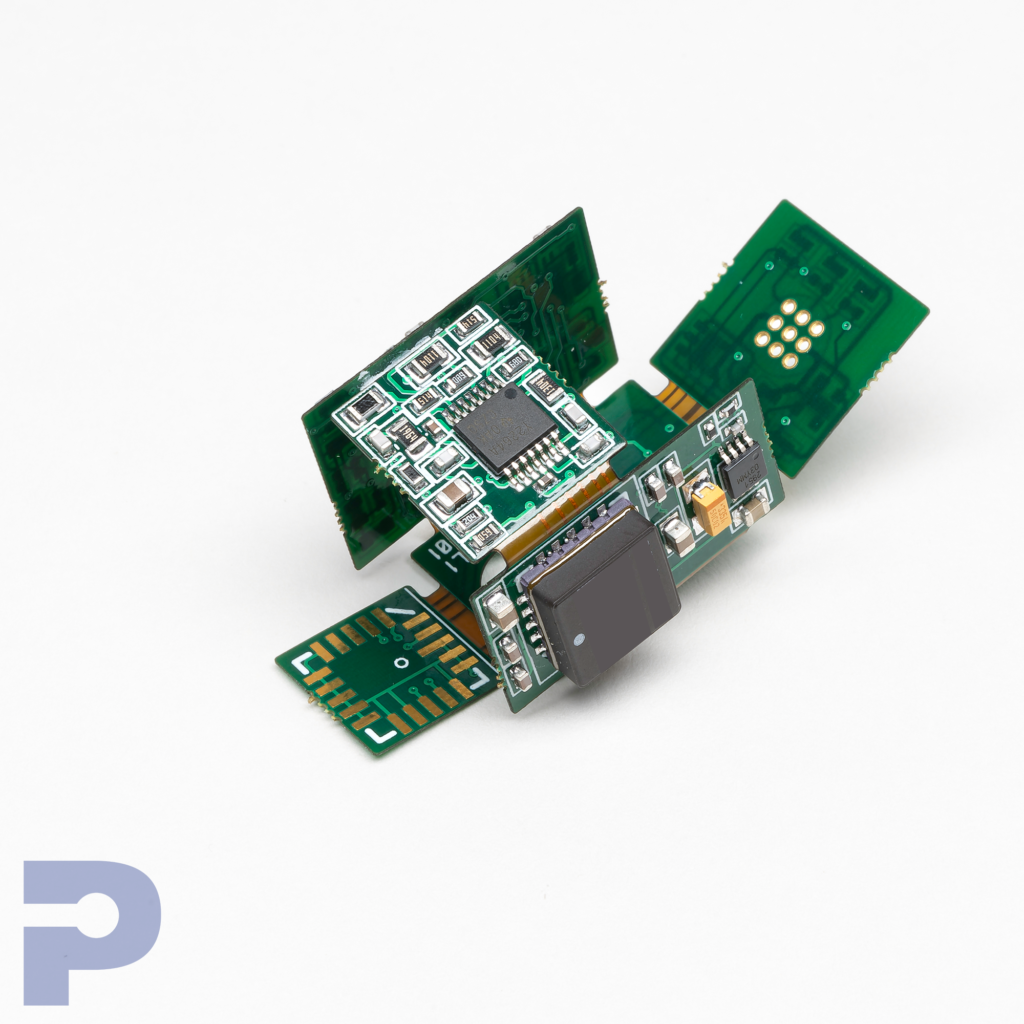

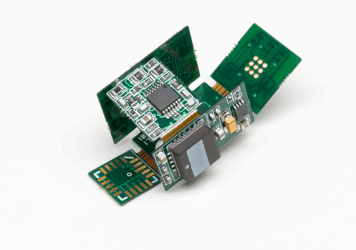

PICA designs and manufactures rigid-flex printed circuit boards (PCBs) that combine the structural reliability of rigid boards with the design freedom of flexible circuits. These hybrid PCBs streamline complex designs, eliminate bulky connectors, and withstand shock and vibration—making them ideal for compact, high-reliability electronics.

Rigid-flex PCBs are trusted in aerospace, defense, medical, automotive, and consumer electronics, where space is limited and performance is mission-critical. With advanced stack-up options, impedance control, and precision assembly, PICA provides rigid-flex PCB solutions that deliver durability, miniaturization, and electrical stability.

Why Choose Rigid-Flex Circuit Boards?

Space-Saving Design – Combines rigid strength and flexible routing in one board.

High Reliability – Fewer connectors reduce failure points in demanding applications.

Durability Under Stress – Superior resistance to bending, vibration, and thermal cycling.

Compact Integration – Ideal for tight enclosures requiring 3D configurations.

Design Flexibility – Supports innovative layouts and high-density interconnects.

Rigid-Flex PCB Capabilities – Highlights

PICA offers full end-to-end rigid-flex circuit manufacturing with advanced materials and processes:

-

Up to 40 rigid layers and 32 flex layers

-

2 mil (50 μm) trace/space for HDI and compact designs

-

Controlled impedance with TDR verification

-

Laser drilling for fine-pitch vias and interconnects

-

Adhesiveless polyimide laminates for ultra-thin flex sections

-

EMI shielding options (copper planes, silver ink, EMI film)

-

High-frequency and high-power design compatibility

For technical information on PICA’s Rigid Flex Printed Circuit Board capabilities, click the button below.

Benefits of Rigid-Flex PCBs / Rigid Circuit Boards

Optimized Space Utilization

Ideal for compact or irregular spaces, rigid-flex PCBs enable device miniaturization without sacrificing performance.

Enhanced Reliability

By removing connectors and cables, rigid-flex designs reduce failure points and improve long-term system reliability.

Superior Durability

These boards withstand vibration, shock, and repeated bending, ensuring stable performance in harsh environments.

Weight Reduction

Lightweight flex materials and fewer connectors make them significantly lighter than traditional rigid PCBs.

Design Versatility

Rigid-flex PCBs support complex 3D layouts, bending, and folding, unlocking innovative, space-efficient solutions.

Markets We Serve with Rigid Circuit Boards / Rigid-Flex PCBs

Consumer Electronics:

Powering compact devices like smartphones, tablets, and wearables with lightweight, space-saving designs.

Medical Devices:

Used in pacemakers, hearing aids, implants, and diagnostics where flexibility and reliability are critical.

Automotive:

Built into control modules, lighting, and infotainment systems to withstand vibration, heat, and irregular layouts.

Industrial Equipment:

Trusted in robotics, sensors, and control systems for durability in harsh environments.

Defense & Security:

Essential in satellites, missiles, and avionics, combining lightweight efficiency with extreme durability.

Why You Should Involve Your Flex Circuit Manufacturer Early in the Design Process

In product development, timing is everything. But too often, the flexible circuit comes late in the conversation,...

Rigid-Flex: The Winning Technology Behind Smart Impact Monitoring Mouthguards

When it comes to sports safety, precision and reliability are non-negotiable. Impact monitoring mouthguards, like those used to measure head...

Flexible Circuits Powering the Next Generation of Drones

Modern drones demand electronic systems that are lightweight, compact, and highly reliable. Traditional rigid PCBs often struggle to...

Using Flex Circuits to Design Smaller, Smarter Electronics: The Smartphone Advantage

From the palm of your hand, smartphones have revolutionized how we connect, work, and navigate the world. But behind the...

Biocompatible Substrates for Flex and Rigid PCBs

In the expanding world of medical devices, and wearables, the demand for biocompatible substrates...

Designing Rigid-Flex Circuits: What Engineers Need to Know

Rigid-flex PCBs combine the best of both worlds—the durability of rigid boards and the versatility of flexible circuits—into a...

Case Study: Innovating Medical Healthcare Technology with Rigid Flex PCB Design

Customer Overview: The customer in this case study is a leading company in the healthcare technology sector, known for its...

6-Layer ELIC Rigid Flex Printed Circuit Board / Rigid Flex PCB

A 6-Layer ELIC (Every Layer Inter-connect) Rigid Flex Printed Circuit Board / Rigid Flex PCB is an advanced and...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.