PCB Assembly Services / FPCBA & PCBA

Custom PCB Assembly Solutions for High-Reliability Electronics

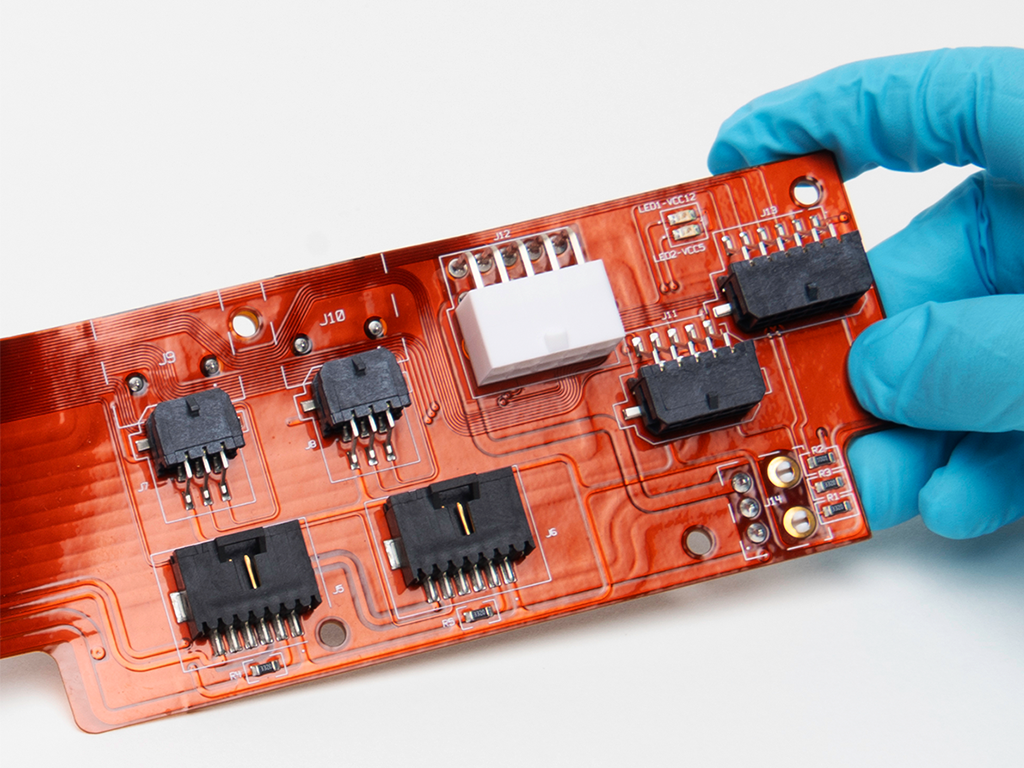

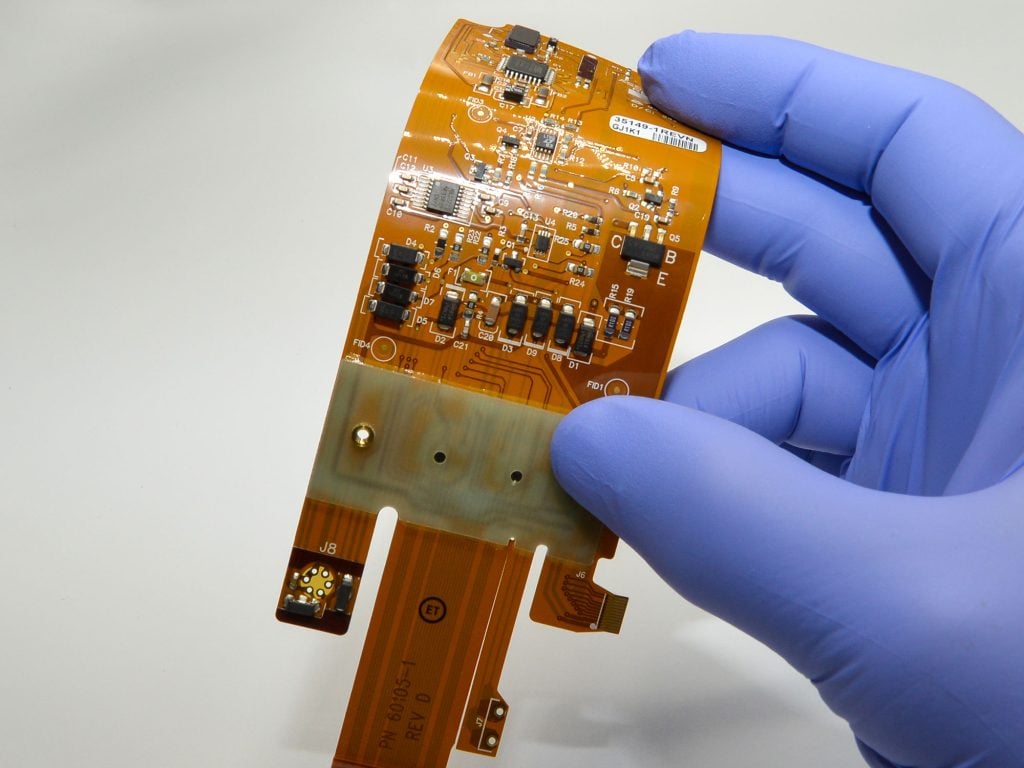

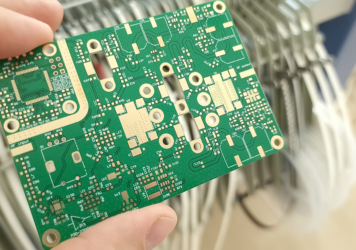

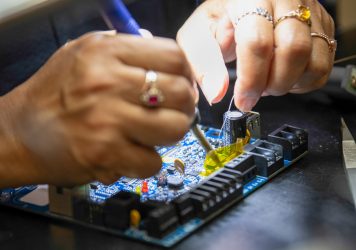

PICA delivers precision component assembly for both rigid PCB builds (PCBA) and flexible circuit assemblies (FPCBA), supporting prototypes through reliable production. With integrated sourcing, kitting, reflow or selective soldering, and quality inspection, we build assemblies that are electrically robust and mechanically dependable. Whether your design requires standard FR-4 PCBs, thin flexible circuits, or rigid-flex interconnects, we optimize the assembly process for performance, yield, and manufacturability.

Our turnkey approach reduces vendor handoffs and engineering uncertainty by managing component placement, wiring, interconnects, encapsulation, and final electrical verification under one controlled process. Customers choose PICA because we balance manufacturability with reliability, support tight dimensional and mechanical constraints, and deliver assemblies prepared for box build or final device integration. By engaging early, our team aligns design decisions with high-volume best practices to ensure predictable outcomes and lower lifecycle risk.

PICA’s component assembly services are used in medical wearables, IoT sensors, industrial controls, energy management platforms, test/evaluation hardware, and advanced consumer devices. Whether you need PCBA support with complex mixed-signal layouts, or FPCBA for thin, bend-capable flexible circuits, we deliver assemblies that perform consistently across prototypes and production. Our engineering support helps streamline documentation, BOM alignment, inspection criteria, and reliability requirements so your assemblies are ready for the next stage.

Why Choose FPCBA & PCBA Assemblies from PICA?

End-to-End Expertise – From bare board fabrication to component sourcing, assembly, and final testing, we provide a seamless, single-source solution.

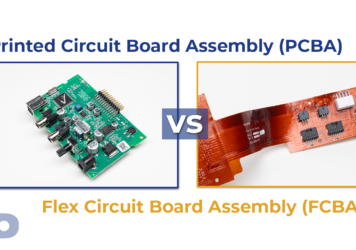

Flexible & Rigid Support – Whether your design requires dynamic flexing or traditional rigid stability, we specialize in both PCBA and FPCBA, giving you the best fit for your application.

Global Capacity – With facilities in the U.S. and Malaysia, we combine responsive engineering with scalable production and logistics support to meet your timelines.

Reliability at Scale – Our process controls, ESD protection, and functional testing ensure assemblies meet stringent performance standards, from prototypes to high-volume runs.

Customized Solutions – Every project is different. We tailor materials, adhesives, stiffeners, and inspection strategies to ensure durability, flexibility, and long-term reliability.

PCB Assembly Capabilities – Highlights

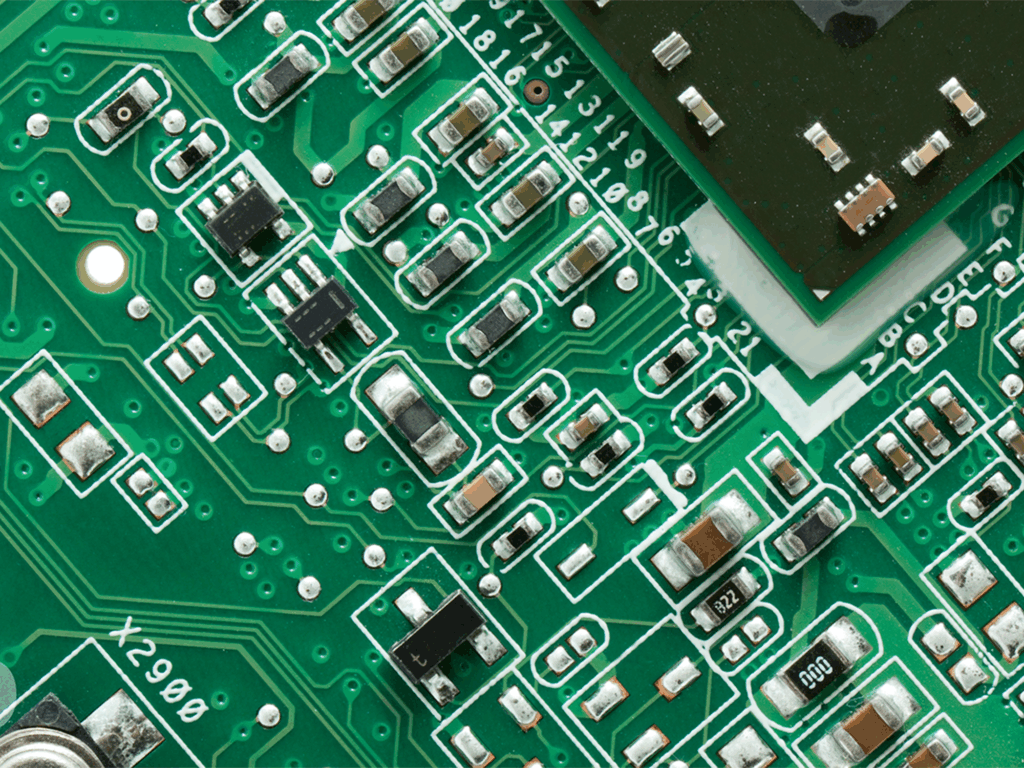

PICA’s component assembly services include advanced techniques and strict process controls:

-

Surface-mount technology (SMT) and through-hole assembly

-

Conformal coating and protective finishes

-

Automated optical inspection (AOI) and X-ray inspection

-

Functional and in-circuit testing

-

DFM analysis and engineering support

-

Prototype to high-volume production readiness

-

Global logistics with U.S. and Malaysia facilities

For technical information on PICA’s Assembly capabilities, click the button below.

Benefits of PICA PCB Assembly

Versatile Assembly

Complete support for both rigid PCB assemblies (PCBA) and flexible circuit assemblies (FPCBA), giving you a single partner for any project.

Comprehensive Services

SMT, through-hole, conformal coating, inspection, and testing are all handled in-house for end-to-end quality assurance.

Reliability & Quality

Every board goes through strict inspection and testing, ensuring dependable performance in critical applications.

Scalable Production

From small prototype runs to high-volume global builds, PICA adapts to your project’s size and timeline.

Engineering Expertise

Our design-for-manufacturing (DFM) support helps optimize layouts, reduce errors, and improve yields before production begins.

Markets We Serve with PCB Assembly

Medical

High-reliability assemblies for implants, diagnostic systems, and surgical tools.

Wearables

Compact, high-density assemblies for wearables, tablets, and smart devices.

Automotive

Durable PCBA and FPCBA assemblies for control systems, lighting, and infotainment.

Defense & Security

Mission-critical assemblies built to endure vibration, shock, and extreme conditions.

Industrial

Rugged assemblies for robotics, automation, and harsh environments.

Understanding the Multi-Purpose Role of Flux in PCB Assembly

Flux is a fundamental material in the electronics manufacturing process, particularly in the assembly of printed circuit boards...

Malaysia: A Thriving Hub for Electronic Manufacturing

Malaysia has emerged as a global hub for electronics manufacturing—thanks to its strategic location, skilled workforce, strong infrastructure, and supportive...

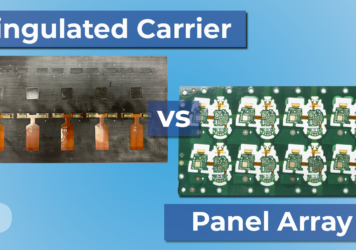

Navigating SMT Assembly Methods for Flexible Circuits

This blog is the first in a two-part series that delves into the critical factors you need to consider when...

Guidelines for Consigning Components & PCBs to PICA

At PICA Manufacturing Solutions, we occasionally receive printed circuit boards (PCBs) and/or components consigned by our customers for their...

Essential Documentation and Data Files for PCB Component Assembly

When ordering component assembly for your Printed Circuit Boards (PCBs) and Flexible Printed Circuits (FPCs), it's important to...

Advance Soldering Techniques for Printed Circuit Board Assembly

Soldering is a critical process that involves joining electronic components to printed circuit boards (PCBs) using a metal alloy,...

PCBAs vs. FPCAs: Understanding the Differences

PCBAs (Printed Circuit Board Assemblies) and FPCAs (Flexible Printed Circuit Assemblies) are both integral to the...

Large Thermal Mass Component Hand Soldering

While mass soldering processes dominate soldering applications, hand soldering remains critical in electronics manufacturing. Existing processes (e.g. convection oven reflow, vapor phase,...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.