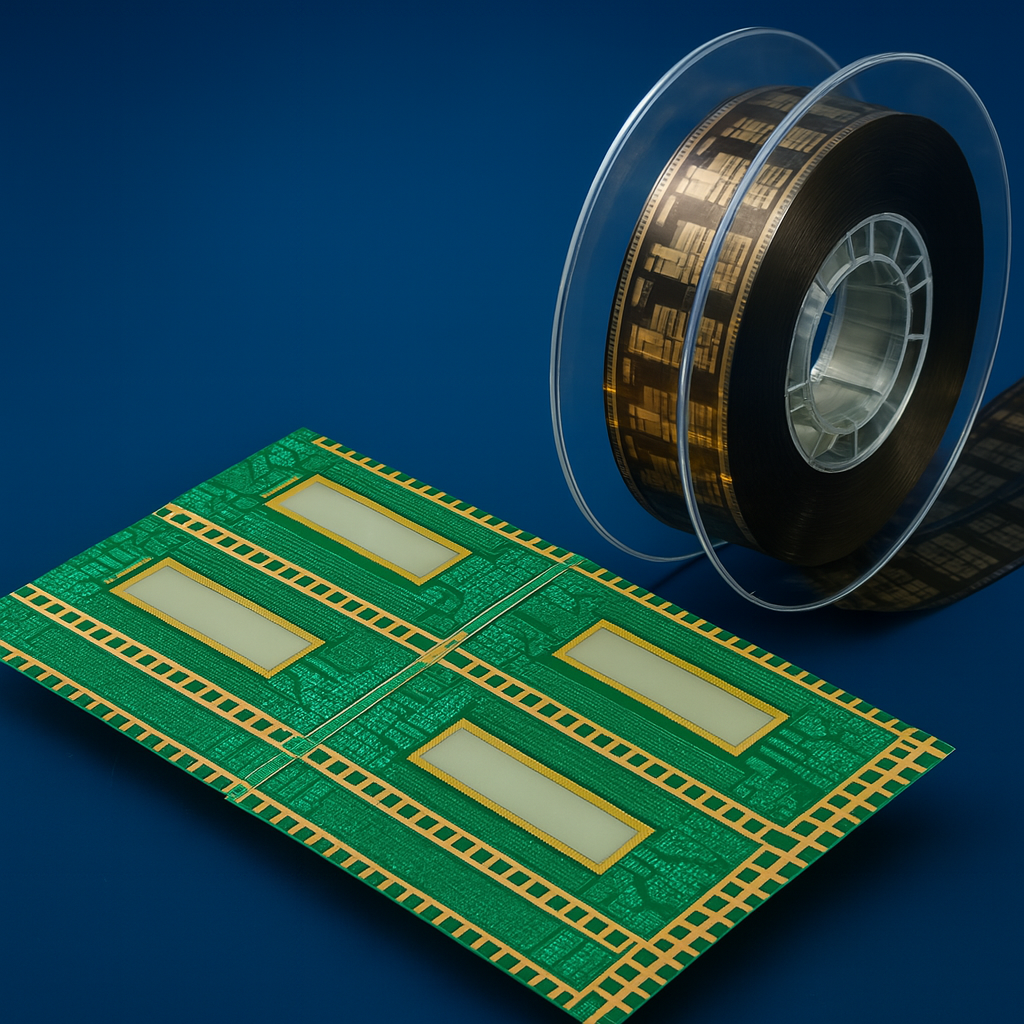

PICA Manufacturing Solutions offers advanced Roll-to-Roll (RTR) processing for high-density flexible circuits that demand precision, scalability, and reliability. Our RTR lines enable continuous production from circuit imaging to final finishing—ideal for compact, lightweight, and high-volume applications in medical, industrial, and consumer electronics.

What is Roll-to-Roll (RTR) Manufacturing?

RTR manufacturing is a continuous fabrication method that processes flexible circuit substrates—such as polyimide—through sequential steps like imaging, etching, plating, and drilling, all without breaking the roll. This streamlined process delivers consistent, scalable results with tight process control.

Why Choose RTR?

RTR is optimized for fine-line circuitry, high throughput, and traceable production. It is commonly used in advanced applications including MEMS packaging, imaging sensors, consumer devices, and medical electronics that require ultra-reliable and repeatable quality.

Benefits of RTR Processing

RTR supports fine features down to 15/15 µm with ±10% tolerance, provides high material efficiency, and offers flexible delivery formats—roll, tape & reel, or singulated. Surface finish options include soft/hard gold, silver, and AgCl. Full unit-level traceability meets the needs of regulated industries.

Limitations

RTR requires upfront investment in specialized equipment and is typically limited to 250 mm web widths. Some designs may require adaptation from panel-based formats, and select finishes are only available through panel processing.

RTR Manufacturing Capabilities

Our RTR systems support web widths up to 250 mm and roll lengths up to 100 meters. Each roll is traceable in both directions, and all production undergoes 100% electrical and camera inspection, First Article buy-off, and AQL-based sampling.

Laser Drilling: UV and pico laser drilling down to 25 μm

Imaging Accuracy: Multi-step exposure with ±25 μm registration

Assembly Support: Chip-on-Flex (COF), flip-chip, wire bond, and MEMS applications

Protection Layers: Coverlay lamination and solder mask application

Advanced Design Support

PICA supports complex design features for demanding applications:

15/15 μm line/space resolution

±10% conductor thickness control

Flying leads, vent vias, and staggered traces under die

Direct gold plating to reduce TCB pad cracking and extend shelf life

Surface Finishes

We offer a range of finishes tailored to application needs:

Soft Gold with Nickel Barrier: 99.9% Au for IC packaging

Direct Gold on Copper: Nickel-free for TAB bonding

Hard Gold with Nickel: Durable AuCo for sliding contacts

Electrolytic Silver: Panel-based for specialized IC packaging

Delivery Formats

Flexible circuits can be delivered in:

Roll Form with full unit-level traceability

Tape & Reel in widths from 14 mm to 70 mm

Singulated or Sub-panel Formats depending on application needs

Unlock the Power of RTR Flex Circuits

Click here to request a quote or speak with our experts to explore how RTR flexible circuits can elevate your next project.