Printed Circuit Boards / PCBs

Custom Printed Circuit Boards Engineered for Performance

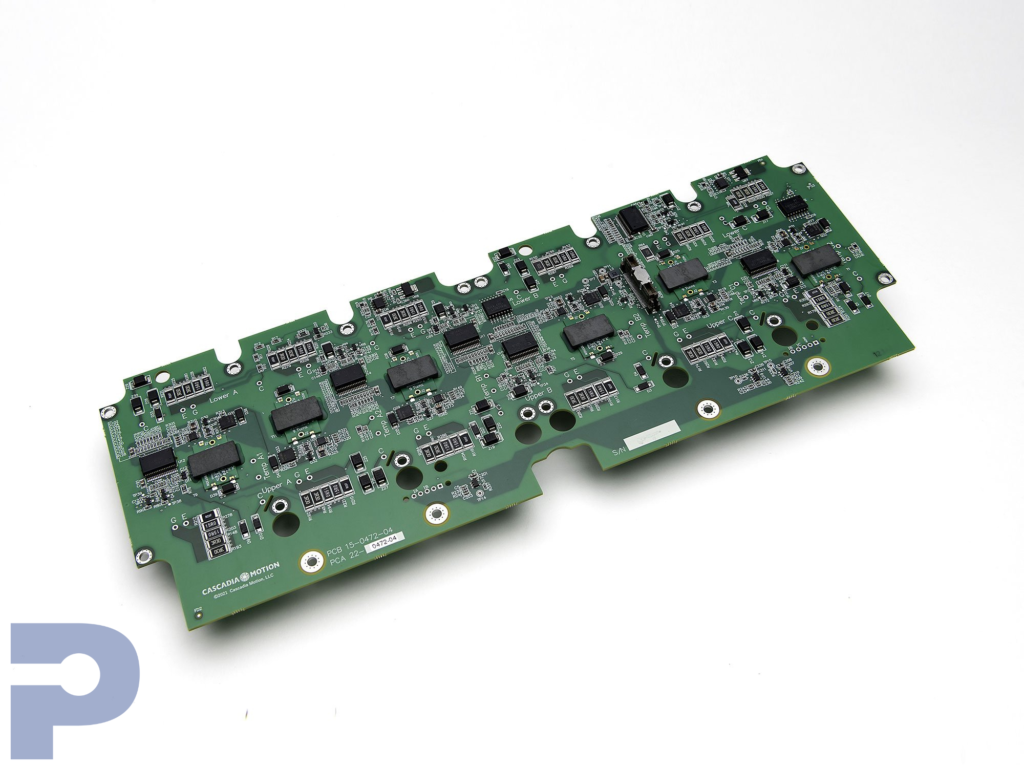

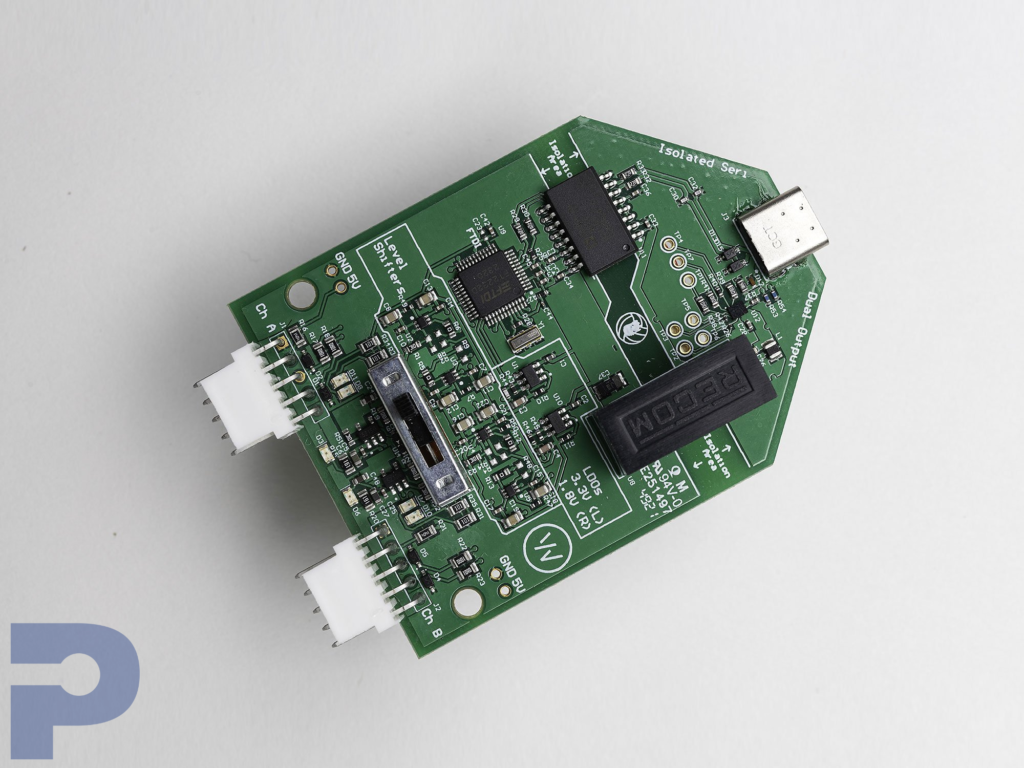

PICA designs and manufactures printed circuit boards (PCBs) that deliver precise, reliable performance across industries. From early-stage prototypes to high-volume production, our team provides scalable PCB fabrication backed by stringent quality control and responsive engineering support.

Trusted in medical devices, industrial automation, communications, wearables, and automotive systems, PICA PCBs are built to meet demanding requirements for signal integrity, durability, and manufacturability.

Why Choose Printed Circuit Boards from PICA?

Proven Reliability – Stable boards produced under strict quality standards.

Cost-Effective Options – Single-sided and double-sided PCBs for straightforward applications.

High-Density Interconnects – Multi-layer and HDI designs for compact, high-performance systems.

Design Optimization – Engineering support for stack-ups, materials, impedance, and thermal management.

Scalable Production – Fast prototypes and high-volume builds with global logistics.

PCB Capabilities – Highlights

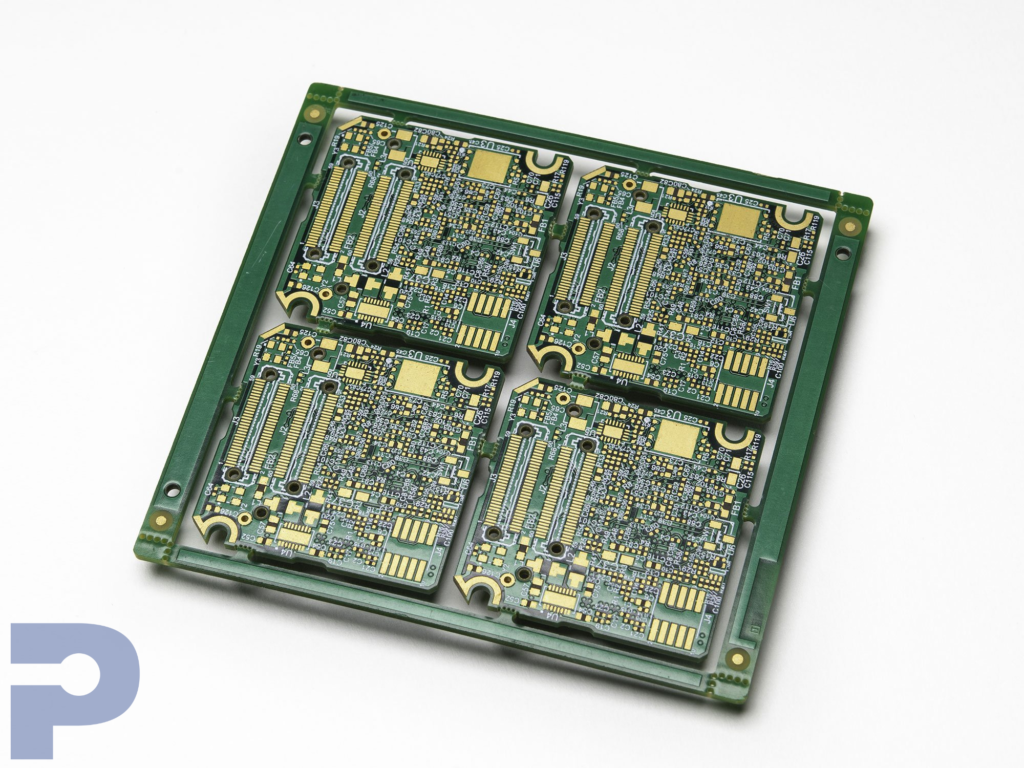

PICA offers full end-to-end PCB manufacturing with advanced processes and materials:

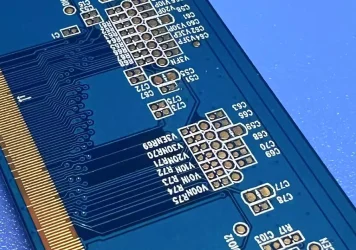

Up to 28+ layers with complex HDI stack-ups

Microvias, blind & buried vias for compact routing

Controlled impedance with TDR verification

Fine-line circuitry for high-speed and miniaturized designs

Material flexibility – FR-4, high-temp laminates, and hybrid constructions

Thermal management – Optimized for heat dissipation and reliability

Regulatory compliance – RoHS, UL, and ISO 13485 certified manufacturing

For more technical information on PICA’s Printed Circuit Boards capabilities, click the button below.

Benefits of Printed Circuit Boards / PCBs

Consistent Quality

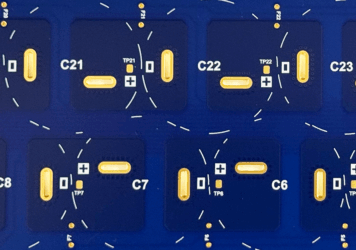

Every board is manufactured under strict process control for long-term reliability.

Design Flexibility

Options from simple single-sided PCBs to advanced multi-layer HDI structures.

Faster Time-to-Market

Quick-turn prototyping and scalable production help you launch products faster.

Optimized Performance

Engineered for signal integrity, thermal stability, and durability in demanding applications.

Global Manufacturing Advantage

U.S. and Malaysia facilities provide cost-effective production with local support.

Markets We Serve with Printed Circuit Boards / PCBs

Consumer Electronics:

Powering compact devices like smartphones, tablets, and wearables with lightweight, space-saving designs.

Medical Devices:

Used in pacemakers, hearing aids, implants, and diagnostics where flexibility and reliability are critical.

Automotive:

Built into control modules, lighting, and infotainment systems to withstand vibration, heat, and irregular layouts.

Industrial Equipment:

Trusted in robotics, sensors, and control systems for durability in harsh environments.

Defense & Security:

Essential in satellites, missiles, and avionics, combining lightweight efficiency with extreme durability.

See What You Can’t See: AOI & X‑Ray Inspection in PCB Assembly

In today’s electronics world, component densities are rising, geometries are shrinking, and reliability expectations are higher than ever. Failures at...

Designing for Edge-Mounted PCBs: Best Practices and Considerations

When space is tight, or when PCBs need to mate with enclosures, panels, or external interfaces, edge-mounted boards can offer...

Mastering Thermal Management in PCB and Flex Circuit Design

As electronic devices become more compact and powerful, managing heat effectively is critical to ensuring performance, reliability, and long product...

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing

Why AOI and Quality Control Matter in PCB and Flex Circuit Manufacturing When it comes to PCB and flex circuit manufacturing,...

Guide to PCB & FPC Manufacturing Processes

This blog is an excerpt from the white paper Guide to PCB & FPC Manufacturing Processes: Subtractive, Semi-Additive & Additive...

Designing High Voltage PCBs: Key Layout and Material Considerations

When working with high-voltage circuits, design priorities shift. While many PCBs focus on high-speed signaling, impedance control, or component density,...

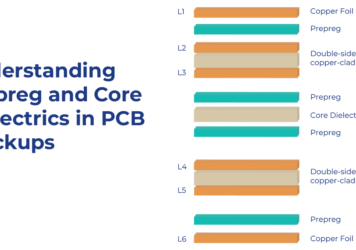

Understanding Prepreg and Core Dielectrics in PCB Stackups

In multilayer PCB fabrication, what connects copper layers together isn’t just glue—it’s carefully engineered dielectric materials that control signal...

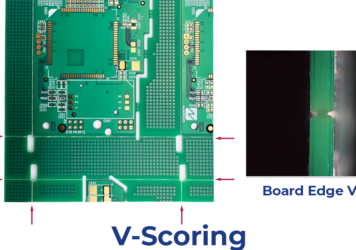

Choosing the Right PCB Separation Method: V-Scoring, Routing, and Die Cutting

Printed Circuit Board (PCB) manufacturing involves precise processes, not just in design and component assembly but also in how the...

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.