Wire Harness Assembly / Custom Wire Harnesses

Custom Wire Harness & Cable Assembly Solutions

PICA designs and manufactures custom wire harnesses and cable assemblies for industries including automotive, medical, aerospace, defense, and industrial systems. By bundling multiple wires into a single, organized assembly, we simplify installation, improve reliability, and reduce weight in complex electronic systems.

With scalable facilities in the U.S. and Malaysia, PICA supports projects ranging from prototypes to high-volume harness production. Our assemblies are engineered for precision, tested for performance, and tailored to your exact specifications.

Why Choose Wire Harnesses?

Streamlined Design – Wire harnesses bundle multiple wires into a single organized unit, reducing clutter and simplifying installation in complex systems.

Improved Reliability – By minimizing loose connections and routing errors, harnesses enhance long-term electrical stability and reduce system failures.

Space & Weight Savings – Consolidating wiring reduces system bulk and weight, which is critical in aerospace, medical, and portable electronics.

Enhanced Protection – Harnesses can be shielded and sleeved, providing defense against abrasion, vibration, moisture, and environmental stress.

Cost & Time Efficiency – Standardized, pre-engineered harnesses cut assembly time, lower labor costs, and simplify future maintenance.

Wire Harness Capabilities – Highlights

PICA delivers end-to-end wire harness solutions with advanced equipment and global capacity:

Simple to complex multi-branch harnesses

Wide range of wire gauges and connector types

Shielded, molded, and custom-labeled options

Automated cutting, stripping, crimping, and testing

Protective sleeving and strain relief techniques

Prototype to high-volume production readiness

Electrical validation and quality testing

Benefits of Custom Wire Harness Assembly

Simplified Installation

Organizing multiple wires into one assembly saves time, reduces labor, and minimizes wiring errors.

Improved Reliability

Pre-engineered harnesses eliminate loose connections, improving long-term electrical and mechanical stability.

Space & Weight Savings

Consolidated wiring reduces system bulk and lowers overall weight, critical for aerospace, medical, and portable devices.

Enhanced Protection

Shielding, sleeving, and overmolding guard against abrasion, vibration, moisture, and environmental stress.

Consistent Quality

Automated cutting, stripping, and crimping ensure repeatable, high-quality harness builds every time.

Markets We Serve with Wire Harnesses

Automotive

Harnesses for control modules, lighting, and infotainment systems designed to withstand vibration and heat.

Defense & Security

Lightweight, rugged harnesses for avionics, satellites, and mission-critical systems.

Wearables

Custom wire harnesses for printers, networking equipment, and compact electronics.

Medical

Reliable wiring solutions for diagnostic equipment, monitoring devices, and therapeutic systems.

Industrial

Durable harnesses for robotics, sensors, and factory automation systems.

Flex PCB Adhesives and Bonding Guide

Thermoplastic vs thermoset adhesives, adhesiveless constructions, and the process factors that drive delamination riskIn flex circuits, reliability...

Flex PCB Substrate Deep Dives Beyond Polyimide

PET vs PEN, LCP, PTFE/fluoropolymers, and specialty films like PEI/PEEK: when each wins, where each struggles, and what it means...

Highlights from MD&M WEST 2026

MD&M West 2026 in Anaheim brought together medtech, automation, design/manufacturing, plastics, and packaging, so the biggest trend wasn’t one...

Tariffs in the United States: History, Reality, and How PICA Helps You Navigate Them

Tariffs have played a role in the U.S. economy since the nation’s founding. In the early days of the republic,...

CES 2026 Highlights: The Breakthrough Technologies Powered by Advanced Flex & PCB Design

Las Vegas, January 2026 — CES 2026 once again confirmed that the pace of innovation in consumer tech, mobility,...

What Is Box Build Assembly? Process, Benefits & How to Choose a Manufacturer

Box build assembly—sometimes called systems integration—involves assembling a complete electronic product by combining a finished PCBA with...

Designing PCBs for Medical Devices: Key Considerations & Compliance Tips

PCB design for medical electronics demands more than just electrical functionality. Devices must meet...

What to Look for in a Manufacturing Company in Malaysia

When evaluating a manufacturing company in Malaysia, most teams are focused on a few essentials: capability fit, reliable quality systems,...

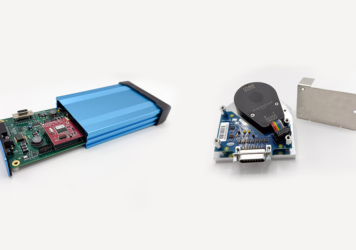

Request Your PICAKit Today

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, & flat flexible cables.