PICA Manufacturing Solutions PICA Flex Sample Kit

This sample kit showcases just a few of the many ways flex circuits can be manufactured. Since every flex circuit is completely custom, the possible variations are nearly unlimited. Key factors that influence design include substrate material, copper foil thickness, trace layout, bending requirements, component placement, controlled impedance, layer quantity, and overall flexibility— considering potential stress points during bending.

Each sample in the PICAKit collection measures 1 inch x 5 inches, pro- viding a tangible and standardized format for engineers to assess and evaluate our technology.

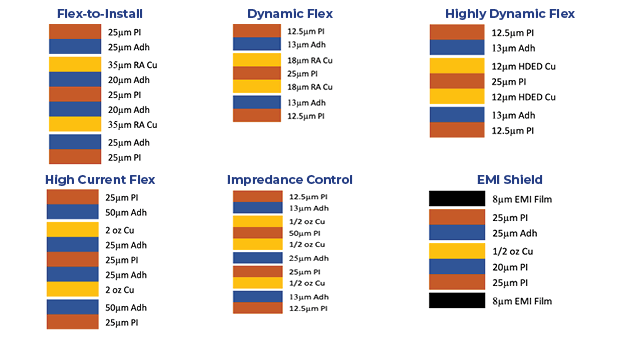

Flex-to-Install

A standard two-layer flex circuit with 35 μm Rolled Annealed (RA) Copper (Cu) on both sides of polyimide film, with an adhesive layer bonding it together.

• Designed for applications with limited flexing, mainly during installation

• Its thicker construction provides a more robust design with limited flexibility requirements

Dynamic Flex

Built for applications requiring repeated flexing, this stack-up includes:

• 18 μm RA Copper (Cu) per layer

• Adhesiveless polyimide, making it thinner and more flexible, which is advantageous for 3D packaging

Highly Dynamic Flex

For continuous bending applications, this stack-up uses:

• 2 μm High-Ductility Electrodeposited (HDED) Copper (Cu)

• Ultra-thin construction for extreme flexibility

• Exceptional endurance in the range of hundreds of thousands to millions of cycles

High Current Flex

Designed for applications requiring high current with minimal bending, this stack-up features:

• 2 oz Copper (Cu)

• Thicker adhesive and base film for better performance

Impedance Control

For designs where components may disrupt signal integrity, this stack-up consists of:

• Three layers of 1⁄2 oz Copper (Cu)

• Two outer layers with polyimide between solid copper, acting as a shield for impedance stability

• Polyimide thickness can vary based on impedance requirements

EMI Shield

For environments where electromagnetic interference (EMI) is a concern, this stack-up includes:

• One layer of 1⁄2 oz Copper (Cu)

• Two outer layers of 8 μm EMI film, protecting sensitive circuits from external noise

• Maintains flexibility while offering EMI protection