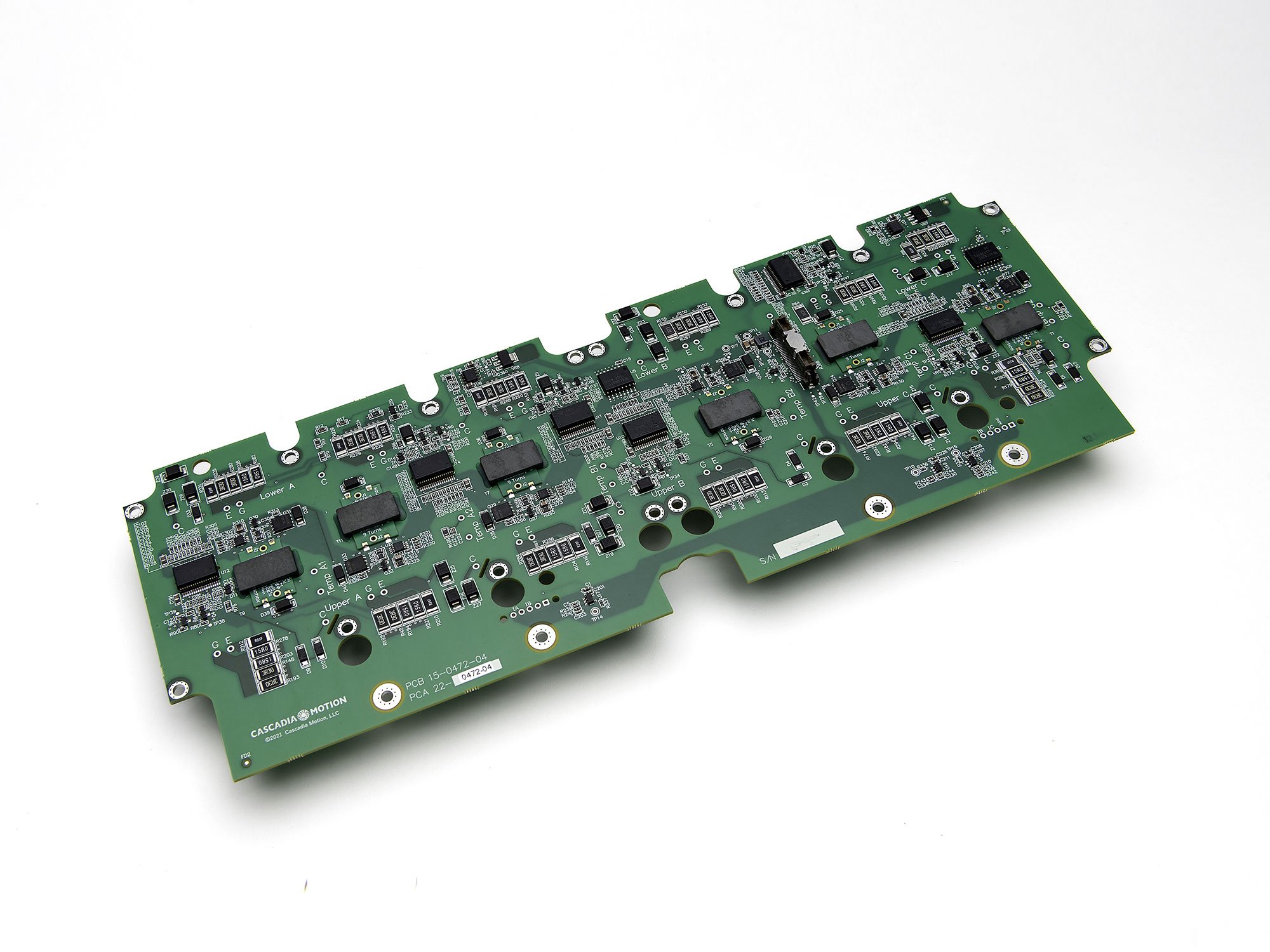

PICA Manufacturing Solutions Industrial Electronics

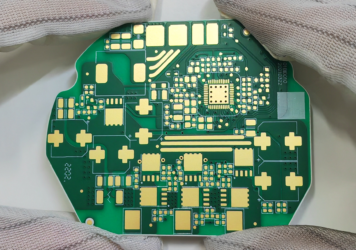

PICA Manufacturing Solutions delivers durable, high-performance printed circuit boards and assemblies built to thrive in demanding industrial environments. From extreme temperatures and high-vibration settings to specialized EMI shielding and custom configurations, our solutions are engineered to keep critical systems operating reliably. Partnering with OEMs and innovators worldwide, we support industrial applications where precision, ruggedness, and long-term performance are non-negotiable.

We enable innovation across a broad spectrum of submarkets:

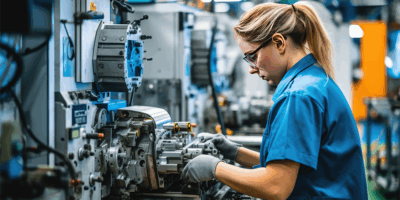

Factory Automation & Robotics

Automation systems demand precise, reliable electronics to keep production lines moving efficiently. PICA provides flex and rigid PCBs and assemblies designed for continuous operation, with features like vibration resistance, extended temperature ranges, and custom board geometries to fit complex robotic designs.

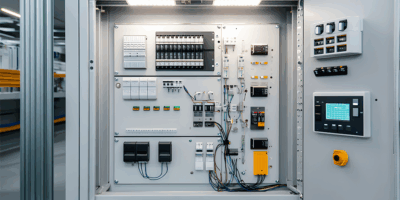

Power Electronics

High-power industrial systems require boards that can handle significant current while maintaining thermal stability. PICA offers heavy copper options, advanced thermal management techniques, and material choices that ensure consistent performance under heavy electrical loads.

Instrumentation & Measurement

Measurement accuracy starts with stable, interference-free circuitry. PICA designs and manufactures boards with enhanced signal integrity, EMI shielding, and rugged construction to support dependable operation in laboratory, field, and production environments.

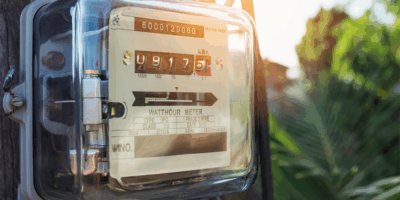

Smart Meters & Grid Devices

Utility infrastructure depends on electronics that can withstand outdoor exposure and years of operation without maintenance. PICA delivers solutions with protective coatings, wide temperature tolerance, and robust connectivity to keep metering and grid systems online and accurate.

Aviation & Aerospace Systems

Electronics for aviation and aerospace and drone technologies require absolute reliability in extreme and mission-critical conditions. PICA manufactures printed circuit boards with strict quality control, lightweight yet robust materials, and proven designs for withstanding high vibration, altitude, and temperature extremes, whether in aircraft, satellites, or unmanned aerial systems (UAS).

Smart City Infrastructure

From traffic management to environmental monitoring, smart city systems need durable, long-life electronics that perform outdoors around the clock. PICA’s manufacturing processes ensure weatherproofing, secure data transmission, and long-term stability in urban networks.

Printing Systems & Digital Imaging

High-speed printing and imaging systems demand precise timing and noise-free operation. PICA builds boards with optimized layouts, high-speed signal capabilities, and robust connectors to maintain performance over years of heavy-duty use.

From factory floors to flight decks, PICA Manufacturing Solutions delivers the reliability, precision, and durability industrial applications demand. Our expertise in advanced flex and rigid PCB manufacturing and assembly ensures your systems perform flawlessly—wherever performance matters most.

Ready to power your next industrial innovation? Fill out our form and let PICA Manufacturing Solutions help bring your project to life.

Designing High Voltage PCBs: Key Layout and Material Considerations

When working with high-voltage circuits, design priorities shift. While many PCBs focus on high-speed signaling, impedance control, or component density,...

Conductive Inks and Their Role in Flexible and Printed Electronics

Conductive Inks and Their Role in Flexible and Printed ElectronicsAs electronics continue to evolve beyond rigid, boxy enclosures, the materials...

Choosing the Right Manufacturing Method for Extra-Long Flexible Circuits

FPC (Flexible Printed Circuit) manufacturing has evolved significantly, with both panel-based and roll-to-roll (RTR) processing methods widely used. Each method...

The Rise of Ceramic Substrate Printed Circuit Board

Ceramic substrate PCBs (Printed Circuit Boards) represent a significant advancement in circuit board technology, especially when compared to traditional...