The PICA team is laser focused on helping you bring your ideas from design to delivery with engineer-driven solutions, impeccable service, and a dependable supply chain network.

Let us help you bring your idea to market.

The PICA Way

Get it Right the First Time.

PICA Manufacturing Solutions is a leader in the Flex PCB and electronics manufacturing categories with unmatched engineering support, customer service and manufacturing oversight. Where other PCB suppliers deliver just parts, PICA is committed to developing a true partnership that ensures the product is designed better, built to be produced on time, and ultimately manufactured correctly.

Our team’s manufacturing expertise and unique approach ensure a smooth efficient process from design all the way to delivery. We know what’s available. We’ve seen the pitfalls. And we have built in-house resources that help you stay ahead of costly issue and away from delays.

Our engineers are involved from the outset of the project. We engage with the customers’ engineers right at the start of the design and development stage of the project. This helps our team understand the product’s application requirements early on and allows for better alignment between customer needs and product design.

One of the most important aspects of the PICA journey is our emphasis on Design for manufacturing (DFM). Our team of experienced professionals both Application and Process engineers works closely with our manufacturing partners to provide valuable insights into the upcoming manufacturing process making sure that the designs are fully and economically manufacturable.

PICA application engineer’s primary responsibility is to bridge the gap between the design of the customer and the capabilities of our manufacturing. By collaborating closely with the customer and the manufacturing engineers, they are able to gain valuable insights into the intricacies of the project.

Our team of highly experienced experts with over 20 years in the industry participates in all aspects or program management including decision making and effective management of even the most complex projects. Providing seamless communications between the customers and global manufacturing sites.

We are always dedicated to doing things right. This is why our team here in North America works on the original package of the PCB and the NPI FA prototype before it is built globally.

At PICA our extensive shipping volume grants us the unique advantage of offering our customers flexibility in their shipping options. We understand that some of our customers may have established relationships with specific carriers or prefer their own shipping methods.

At PICA we consider cost optimization a critical part of the manufacturing process. From concept to high volume, we are always looking for ways to maximize efficiency and minimize expenses at every stage.

PICA Manufacturing is dedicated to continuous improvement and ensuring a positive customer experience. We have incorporated a comprehensive approach to making sure that we are always providing our customers with the best possible PCB solutions through continuous process improvements.

As part of our intense customer care, we are always preparing for possible capacity ramp-ups. By having a complete knowledge of our customers’ needs based on ordering and usage trends as well as life of current partners we are able to help predict and prepare for possible capacity ramp-ups as they occur.

PICA Manufacturing works closely with all of its’ manufacturing sites to make sure that they are producing the best products possible with a process that includes matching technologies with the appropriate well-suited companies.

The HUMAN Touch

Real People—Real Solutions

Behind all of your interactions with PICA is a real human and a team that always has your back. We’re a family-owned business that goes above and beyond to understand your needs, eliminate problems, and treat you just like that – family.

Market Segments

“We are a large family at PICA, literally and figuratively.”

LINDSAY IRVING

CFO

Request Your PICAKit Today

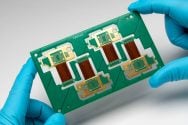

We want you to take a look at what we can produce for you by offering you a PICAKit which includes a variety of flexible pcb, shields, and flat flexible cables.