PICA Manufacturing Solutions Automotive Industry

PICA Manufacturing Solutions produces high-reliability flex and rigid PCBs and assemblies built to perform in the harsh conditions of the automotive industry. Designed to resist vibration, temperature extremes, and electrical interference, our solutions meet rigorous quality and safety standards while supporting innovations in electric vehicles, driver assistance, and smart in-cabin technology.

We enable innovation across a broad spectrum of submarkets:

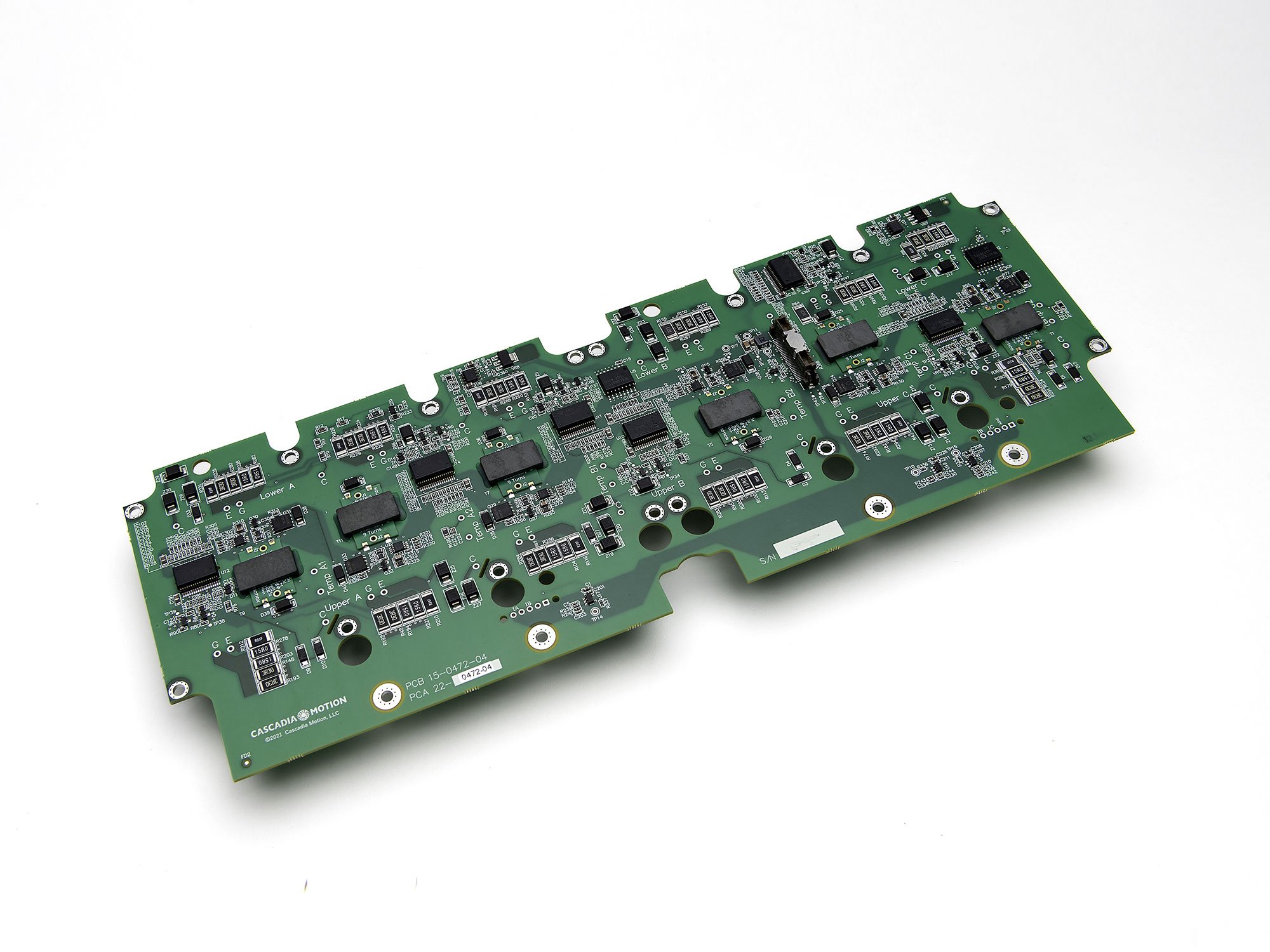

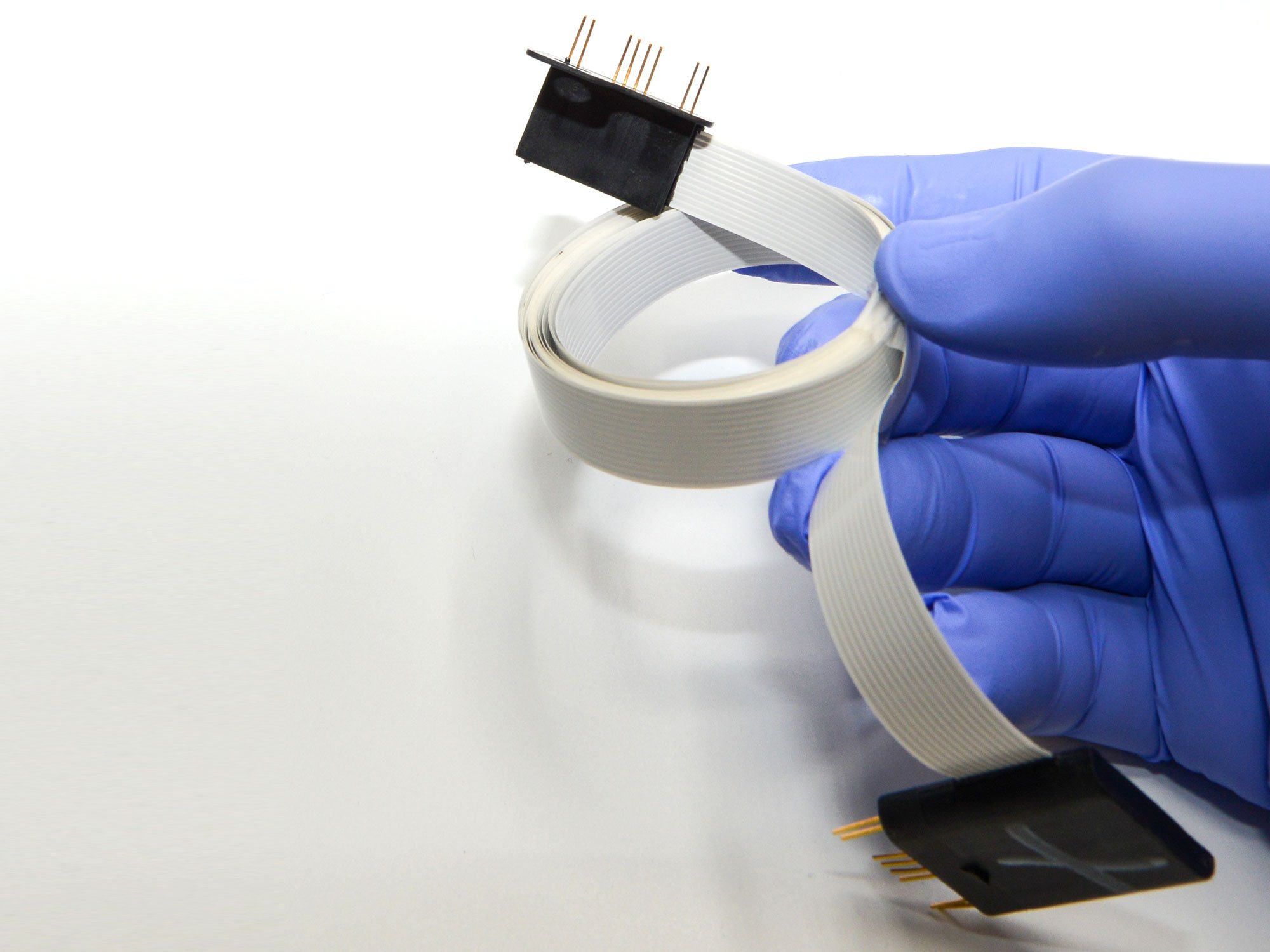

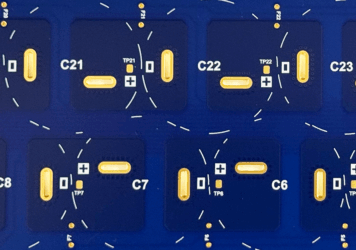

EV Battery Management Systems

Automotive battery management requires precision electronics that can withstand the heat, vibration, and safety demands of high-capacity energy storage. PICA manufactures boards and flexible interconnects to meet strict industry certifications, ensuring consistent performance over a vehicle’s lifetime.

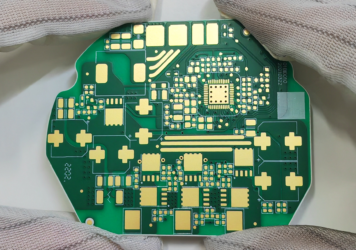

ADAS Modules

Advanced driver assistance systems rely on radar, lidar, and camera control boards with efficient thermal management. PICA designs and produces high-performance flex and rigid PCBs that maintain stability and signal integrity in critical safety applications.

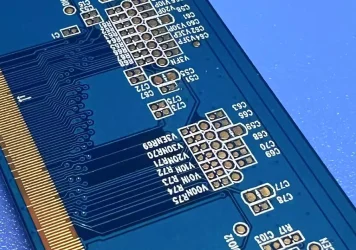

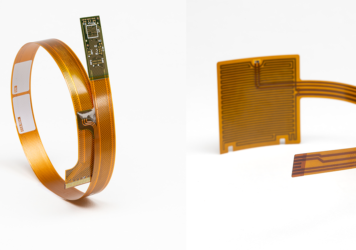

Infotainment & Displays

Touchscreens and flex-to-rigid assemblies require both EMI compliance and flawless signal transmission. PICA provides flex and rigid PCB solutions that deliver responsive performance while integrating seamlessly with vehicle interiors.

Lighting Systems

Smart LED modules and adaptive lighting demand reliable power delivery and electrical safety. PICA’s designs prevent arcing, insulation breakdown, and other hazards to ensure dependable, long-lasting illumination.

In-Cabin Health & Monitoring

Driver fatigue detection and biometric monitoring electronics must perform accurately under continuous use. PICA develops PCBs that balance sensitivity, durability, and integration for next-generation in-cabin safety features.

PICA Manufacturing Solutions combines rugged design, strict quality control, and advanced manufacturing to power the future of automotive technology—from EV batteries to intelligent lighting and safety systems.

Drive your innovation forward. Fill out our form to see how PICA can deliver the high-reliability flex and rigid PCBs your automotive applications demand.

Guide to PCB & FPC Manufacturing Processes

This blog is an excerpt from the white paper Guide to PCB & FPC Manufacturing Processes: Subtractive, Semi-Additive & Additive...

Designing High Voltage PCBs: Key Layout and Material Considerations

When working with high-voltage circuits, design priorities shift. While many PCBs focus on high-speed signaling, impedance control, or component density,...

Understanding Copper Limits & Bend Radius in Flex PCBs

Whether you're designing for a high-durability dynamic application or a compact static installation, every detail matters—from copper type and thickness...

The Rise of Ceramic Substrate Printed Circuit Board

Ceramic substrate PCBs (Printed Circuit Boards) represent a significant advancement in circuit board technology, especially when compared to traditional...